FIBER SENSORS: In-fiber microcavity acts as strain sensor

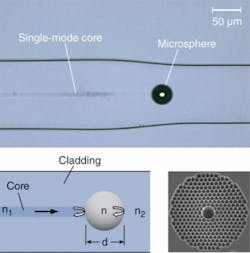

Researchers Gang-Ding Peng from the University of New South Wales (Sydney, Australia) and Enbang Lin and Xin Ding from Tianjin University (Tianjin, China) have developed a fiber-optic Fizeau interferometric strain sensor made of an in-fiber spherical microcavity of 39 mm diameter, formed by splicing an ordinary single-mode fiber with a hollow-core photonic-crystal fiber.

The researchers showed that strain sensing can be achieved by using the interference between the light reflected by the front and rear surfaces of the microcavity.

Light transmitting down the core of the single-mode fiber is partially reflected by the air-silica interface (the front surface of the microcavity) when the light reaches the microcavity. The transmitted light is reflected by the air-silica interface (rear surface) back to the fiber core and interferes with the light reflected by the front surface. The light beam exiting from a right-angle cleaved single-mode fiber can be modeled as a Gaussian beam, with a beam waist at the fiber end surface and a waist diameter equal to the mode-field diameter of the fiber.1 Therefore, the researchers said, the interference process can be treated by using a Gaussian-beam model and the so-called ABCD law (an equation used to simplify calculations in Gaussian optics, in which A, B, C, and D are parameters of the optical system).2,3

The reflectivity at the air-silica interfaces is low—less than 4%—and therefore multiple reflections can be neglected; however, for the same reason, the interferogram itself is weak. Because the wavelength is used as an indicator of the measured strain, this will not affect the measuring accuracy as long as an interference peak or trough can be identified.

An axial strain applied to the fiber segment containing the microcavity alters the cavity’s length, changing the wavelength corresponding to the interference maximum. By measuring the wavelength shift, it is possible to determine the variation of the cavity diameter and the strain experienced by the fiber segment containing the microcavity.

The sensor is relatively insensitive to temperature, having a sensitivity of only 1.35 pm/°C, making temperature compensation unnecessary for most applications. A strain sensitivity of 3.36 pm/me can be achieved, which is a much higher sensitivity than that of most fiber-Bragg-grating strain sensors.

The spectral range of the light source used in the experiments (1530 to 1560 nm) allowed detection of only one minimum and one maximum; the spacing between them was measured as 15.5 nm, indicating a change in wavelength of 31 nm. Using the measured value of the microcavity diameter and taking the refractive index of air as 1 and the wavelength as 1550 nm, the researchers calculated the change in wavelength as 30.8 nm, in good agreement with the experiment.

REFERENCES

1. D. Marcus, Bell Syst. Tech. J. 56, 703 (1977).

2. H. Kogelnik and T. Li, Proc. IEEE 54, 1312 (1966).

3. R.C. Gauthier et al., Appl. Opt. 42, 1610 (2003).

Paul Grad | Freelance writer

Paul Grad is a freelance writer based in Sydney, Australia.