ALKALI LASERS: Demonstrations show advance of alkali lasers

Progress is being made in the development of diode-pumped alkali-vapor lasers, according to a paper presented by Boris Zhdanov, research professor in the Laser and Optics Research Center of the United States Air Force Academy (USAFA; www.usafa.af.mil), at Photonics West (San Jose, CA; see page 20) in January. These lasers offer a number of desirable features compared to other lasers, he said, including the potential to be scaled to higher powers.

Despite their advantages, alkali-vapor lasers have a tendency to become contaminated with carbon (soot)—a product of the alkali atoms reacting with ethane (producing the alkali hydrate and carbon). Zhdanov noted that there are two possible solutions to this problem. One is to operate the alkali-ethane laser at temperatures below 100°C and at a pressure of about 1 atmosphere. Another is to use a buffer gas, such as helium (He), which is not chemically active with alkalis.

This latter approach was described by Sheldon Wu of (LLNL; Livermore, CA) in a presentation preceding Zhdanov’s.1 Wu described the first demonstration of an optical-resonance-transition 795 nm Rb laser with a hydrocarbon-free buffer gas (helium). He said that his group’s results demonstrated all of the advantages of the original alkali-laser system, but without the reliability issues associated with the use of ethane.

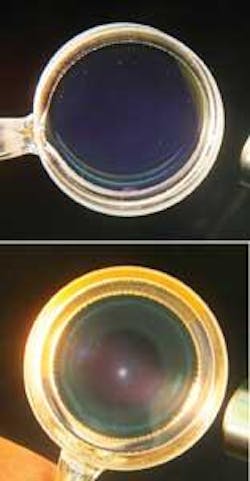

Another hydrocarbon-free alkali laser, a potassium-helium system, was described in Zhdanov’s presentation (see figure). This system was demonstrated at the USAFA at the same time as the Rb-helium laser was demonstrated at LLNL. Unlike the Rb-He laser, this K-He device operates with buffer gas pressure below 1 atmosphere, emitting at 770 nm.

Desirable features

Zhdanov began his presentation by posing the question: “Why alkali lasers?” The answers are multiple, he maintained. First, alkali lasers combine several positive aspects of the best laser systems. They provide excellent optical quality of the gain medium (gas), offer efficient diode-laser pumping, and can be scaled to higher powers. Furthermore, these lasers eliminate several negative features of other laser systems: they do not involve handling large quantities of hazardous chemicals, are limited in size and weight, operate closed cycle (involving minimal logistics), and they offer reduced thermal management issues with easy heat removal.

Alkali lasers also exhibit high quantum efficiency—95.3% for cesium (Cs), 98.1% for rubidium (Rb), and 99.6% for potassium (K), versus 76% for a 1064 nm Nd:YAG laser—and emit at wavelengths in atmospheric transmission windows. Alkali lasers can be an alternative to diode-pumped solid-state and chemical lasers, Zhdanov said.

Noting that an optically pumped alkali-vapor laser was first proposed in 1958 by Schawlow and Townes, Zhdanov detailed the history of these devices and their progress since then. From 1961 through 1980, various alkali lasers of low power and low efficiency were demonstrated. From 1980 through 1990, the key theory of three-level pumping was developed. Between 2003 and 2004, efficient Rb (54%) and Cs (59%) systems with Ti:sapphire laser pumps were demonstrated at LLNL.

In 2005, the first diode-pumped Cs laser (with 41% slope efficiency) was demonstrated by scientists at the USAFA, who subsequently demonstrated an 81%-slope-efficiency Cs laser and the first K laser in 2006. Subsequently USAFA researchers demonstrated a high-power diode-pumped Cs laser (10 W CW, 68% slope efficiency). Most recently they demonstrated a high-power, diode-pumped Rb laser producing 17 W CW, with 53% slope efficiency.

REFERENCES

1. S.S.Q. Wu et al., Photonics West 2008 (Jan. 21, 2008).

MIKE O’NEILL is a freelance science writer living in San Francisco, CA; e-mail: [email protected]