Fiber-optic Sensing: Simple, rugged fiber-optic pressure sensor works over large temperature ranges

Ed. note: It has been pointed out to us by António Lobo Ribiero of University Fernando Pessoa (Porto, Portugal) that he and his colleagues demonstrated a similar device back in 1996: see L. A. Ferreira et al., "Simultaneous displacement and temperature sensing using a white light interrogated low finesse cavity in line with a fiber Bragg grating," Smart Mater. Struct. 7 (1998). A PDF copy of the paper is available at http://homepage.ufp.pt/alobo/page8/page10/files/SMS7_189.pdf.

Fiber-optic pressure sensors that operate at elevated temperatures are useful for downhole sensing in oil wells, testing steam and jet turbines, and high-temperature industrial processes. One popular form of this type of sensor is the Fabry-Perot (F-P) sensor, which contains a pair of parallel optical surfaces forming a F-P cavity at the end of an optical fiber. Pressure-induced deformation of one of the surfaces changes the resonance frequencies of the cavity, which can be sensed optically through the fiber.

However, such a design is usually sensitive to both temperature and pressure, interfering with any measurements intended to just capture pressure data. Thus, this type of sensor usually requires some way to subtract out the temperature dependence of the sensor. Many approaches to decoupling the temperature effects from the pressure effects have been studied and implemented. Now, a group of researchers at North University of China (Taiyuan, China) has come up with a particularly simple way to achieve this decoupling.1

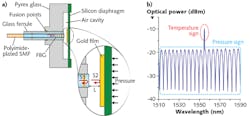

In the new design, a fiber Bragg grating (FBG) at the end of the fiber, terminating in one of the F-P cavity mirrors, adds a temperature-induced spike to the F-P spectrum (see figure) that allows temperature effects to be subtracted out from the raw data, leaving only pressure data. The fabrication method developed by the researchers is also simple and leads to a rugged sensor based on micro-electromechanical systems (MEMS) technology. The sensor has three parts that are combined: the fiber, a silicon diaphragm that deflects under pressure, and a glass ferrule.

Silicon and glass F-P cavity

The researchers start by photolithographically creating circular spots of gold film on one side of a silicon wafer. Then, using photolithography and an etching step creates larger circular depressions on the other side of the wafer centered on the gold spots, thinning the wafer enough to form flexible diaphragms. A Pyrex glass plate is mechanically machined to form a number of pieces with central depressions—these pieces are then fused to the silicon wafer over the diaphragms using a carbon dioxide (CO2) laser. The result is a batch of F-P cavities on the wafer, which is then diced to separate the various cavities.

Finally, for each F-P cavity, a polyimide-plated single-mode fiber (SMF) with an embedded FBG is well-cut near the grating region and is inserted into a small glass ferrule, holding it in place. The ferrule is then fused to the glass/silicon F-P cavity.

The design thickness and radius of the F-P cavity are 95 µm and 1.5 mm, which produce a calculated 7.89 µm/MPa sensitivity. If the largest deformation of the diaphragm is restricted to no more than 20% of its thickness, then the maximum pressure the diaphragm should be subjected to is approximately 2.41 MPa at room temperature.

A completed sensor was placed in an argon-filled tank in which pressure and temperature could be varied. The fiber-optic sensor was connected to an optical analyzer and a computer, and a thermocouple near the sensor monitored temperature. In the experiment, pressure was varied from 0 to 0.5 MPa in 0.05 MPa steps, then brought back down to 0 using the same step increments. This was done for temperatures of 20°, 100°, 200°, 300°, and 350°C.

As expected, the zero point and sensitivity measured with the F-P cavity shifted with temperature in a linear fashion. In addition, the FBG simultaneously measured pressure and temperature at different sensitivities, allowing the temperature and pressure measurements to be decoupled via calculations. The maximum pressure-measurement error after decoupling was determined to be <1.05% over the entire measured temperature and pressure ranges.

The researchers say that their new sensor has the advantages of batch fabrication, high uniformity, and low cost.

REFERENCE

1. P. Jia et al., Appl. Opt. (2018); https://doi.org/10.1364/ao.57.006687.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.