In Vivo Imaging: All-optical setup makes ultrasound flexible

One of the most common approaches to medical imaging, the ultrasound technique, is limited by hardware bulkiness and integrated electronics that are incompatible with magnetic-resonance imaging (MRI) and other technologies. Now, researchers at University College London (London, England) have demonstrated an all-optical ultrasound probe that can be safely used with MRI. What’s more, it can be miniaturized, and its innovative optics make it more flexible. Thus, it promises to dramatically boost the technique’s application potential.

Although other all-optical ultrasound systems had previously proven able to generate high-quality 2D and 3D imagery, these systems required minutes or hours for image acquisition. The researchers note that theirs is the first all-optical ultrasound system able to produce video-rate 2D imaging of biological tissue in real time.

“Through the combination of a new imaging paradigm, new optical ultrasound generating materials, optimized ultrasound source geometries, and a highly sensitive fiber-optic ultrasound detector, we achieved image frame rates that were up to three orders of magnitude faster than the current state-of-the-art,” says Erwin Alles, lead author of a paper describing the work.1

Comparison to conventional ultrasound

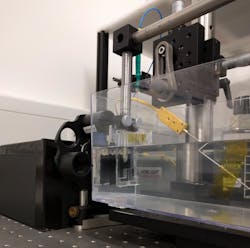

In conventional ultrasound systems, arrays of electronic transducers send high-frequency sound waves into tissue and then receive the sound-wave reflections, which a computer uses to construct images. By contrast, the all-optical imager uses laser light to transmit and receive the sound: Pulsed light generates ultrasound waves and scanning mirrors direct transmission of these waves into the tissue. On the receiving end, a fiber-optic sensor reads the reflected sound waves (see figure).

The traditional electronic components for ultrasound make the hardware difficult to miniaturize, so existing devices are applied externally to the body. Ultrasound probes designed for minimally invasive application are too costly for routine clinical use. In contrast, optical components are easily miniaturized, and the researchers say that manufacturing ultrasound probes based on optics would cost significantly less than production of compact electronic ultrasound systems. In fact, Ales notes, such probes are potentially a fraction of the cost of their conventional counterparts.

Finally, systems based on optics are inherently more versatile than those based on electronics because they can produce sound that has a larger bandwidth. Acquiring different types of ultrasound images with a traditional setup requires use of separate probes. The new device incorporates scanning mirrors that enable acquisition in different modes. This means that in a clinical setting, a doctor could use a single instrument to quickly and seamlessly switch between 2D and 3D imaging, and to trade off between low frequency, which penetrates deeper into tissue, and high frequency, which enables higher resolution. This capability is key since the need to swap imaging probes is not only disruptive, but also lengthens procedures and increases patient risk.

Key concepts

Ultrasonic imaging requires transmitting or receiving from multiple locations—a 1D array is needed for 2D imaging, while a 2D array is necessary for 3D imaging. Electronic probes are made up of arrays with hundreds to thousands of transducers that are individually addressed in quick succession. While previous work in all-optical ultrasound has centered on optimizing performance (of individual sources and receivers, or of single-element fiber-optic probes), 2D or 3D imaging with a single source and receiver pair is impractical for in vivo applications.

A handful of new design concepts are key to the new system, which is sufficiently sensitive to image deep into biological tissue in real time. Among these was an optical sound-generation surface, incorporating carbon nanotubes and elastomeric polymer and suspended in free space; a high sensitivity, fiber-optic acoustic receiver; and cylindrical optics for eccentric illumination, which produces a directive acoustic source.

A fast galvo mirror facilitates scanning of the source across a 1D source aperture and produces dynamically reconfigurable source arrays made up of nonuniformly separated, spatially overlapped sources for reduced artifacting. Together, these components enabled achievement of a 15 Hz sustained frame rate, 30 dB dynamic range, penetration to 6 mm or more, and 75 × 100 µm resolution. These capabilities came together to enable experimental imaging, for instance, of a pulsating ex vivo carotid artery.

To adapt the technology for clinical use, the researchers are working to develop a long, flexible imaging probe for free-hand operation, as well as miniaturized versions for endoscopic applications.

REFERENCE

1. E. J. Alles et al., Biomed. Opt. Express, 9, 3481–3494 (2018).

Barbara Gefvert | Editor-in-Chief, BioOptics World (2008-2020)

Barbara G. Gefvert has been a science and technology editor and writer since 1987, and served as editor in chief on multiple publications, including Sensors magazine for nearly a decade.