High-intensity gas-discharge (HID) lamps produce 26% of the artificial illumination in the U.S. but only consume 17% of the electrical energy used for lighting because of their high efficiency. While the luminous efficacy of incandescent lamps is limited to less than 20 lumens per watt, the luminous efficacy of HID sources can be as high as 125 lumens per watt. The lamps work by drawing a current of a few amperes through a high-pressure gas (usually mercury) that has been dosed with metal atoms known to be strong radiators of visible light.

High-intensity gas-discharge light sources are a key focus of the High Efficiency Distributed Lighting program at DARPA, which is focused on developing high-efficiency remote-source fiberoptic-distributed lighting systems (see Laser Focus World, December 2003, p. 62).

Despite the high luminous efficacy of metal-halide HID lamps, however, the full scope of their operating characteristics is not entirely understood. Ongoing research seeks better understanding in hopes of improving luminous efficacy and color quality (measured in terms of color-rendering index) even further, according to John Curry, a research scientist at the National Institute of Standards and Technology (NIST; Gaithersburg, MD).

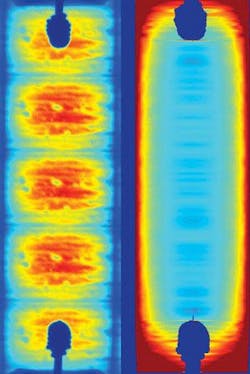

Working with colleagues at NIST and the Argonne National Laboratory (Argonne, IL), Curry has used monochromatic x-rays from the Advanced Photon Source (APS) at Argonne to study the temperature distributions in HID lamps. The same group has also used another technique called x-ray-induced fluorescence to study distributions of light-emitting atoms in these lamps. The information obtained is often presented in color-coded plots (see figure).1

The ability to work with monochromatic x-rays from the APS has made a big difference in the accuracy with which the temperature distribution can be measured, and therefore in the ability to answer important questions—for instance, concerning the extent and origin of undesired thermal- and IR-radiation losses within the lamp, Curry said. The researchers are currently demonstrating that the technique can be implemented in industrial laboratories using small-scale x‑ray sources. The project is also providing measurement support to the Advanced Light Source Research Program-II of the Electric Power Research Institute (Palo Alto, CA).

REFERENCE

1. J. J. Curry and C. J. Sansonetti, IEEE Trans. on Plasma Science 33(2) 514 (April 2, 2005).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.