Popular in science fiction these days are stories of micro- or nanorobots that travel together in great swarms, communicating and working together to achieve some goal for good or evil. As is often the case, however, nature has already trumped technology, in the form of social insects. Bees, for example, are sturdy and highly mobile and operate in cooperative groups.

For years, a group led by Jerry Bromenshenk at the University of Montana (Missoula, MT) has pursued the goal of using bees to sense chemicals in the environment, either by bringing trace amounts of substances back to the hive or by sniffing them out, revealing their locations. The latter approach is being taken in a project to detect the location of buried land mines by the trace amounts of chemicals they give off. Although dogs can also find land mines by smell, they are large enough that they can set the mines off; artificial chemical-sensing techniques require that equipment be set up in the minefield-a dangerous proposition.The bees are trained by Bromenshenk’s group by placing small amounts of the target chemical into feeders, spurring the bees to go out and find other sources of the chemical while foraging. Once the bees congregate around a source, however, their locations must be detected. That portion of the project is being conducted by researchers at Montana State University (Bozeman, MT) who, along with scientists from the National Oceanic and Atmospheric Administration’s Environmental Technology Laboratory (Boulder, CO) developed a lidar system that provides a map of bee density over a large area.1

A 44 × 24-m field implanted with live, but defused, mines and an adjacent 83-m-long mine-free region were used as the area under test. 2,4-dinitrotoluene, a byproduct of the explosive TNT, was chosen as the test substance, as it is commonly found in minefields at concentrations of 0.01 to 100 parts per trillion-levels detectable by bees.

The lidar system was built around a 532-nm-emitting frequency-doubled linearly polarized Nd:YAG laser that emits 10-ns, 100-mJ pulses at a 30‑Hz repetition rate; its beam was horizontally scanned across the field. A 17.5‑cm-diameter refractive telescope with an adjustable linear polarizer collected the backscattered light and directs it to a photomultiplier tube.

The beam was scanned across mined and mine-free regions; its spot size ranged from 30 cm at the front of the minefield to 45 cm at the far end. Two other techniques were also used to detect the bees: a video count based on video cameras located within the mine-field; and a visual count by researchers walking slowly through the field. In addition, chemical sampling was done by a sensor-toting researcher walking through the field.

Depolarization measurements

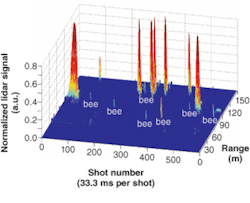

The researchers took lidar bee measurements with copolarized and cross-polarized configurations, noting that a typical mean depolarization ratio (ratio of cross-polarized to copolarized signals) for bees was 0.39 ±0.1. In the mine-field bee-density plots, individual bees appeared as spikes (see figure). Along with sensing the chemical plumes in the minefield, the bees also found an unsuspected plume in the supposedly mine-free area, subsequently confirmed by the chemical sampler. The laser beam appeared not to disturb the bees as they foraged, although shining the beam directly on the hive agitated the bees.

Because bees fly relatively low to the ground, the combination of a fixed-height laser sweep and varying terrain prevents optimal detection. There are workarounds, however. “One possibility is to scan from different locations,” says Joseph Shaw, one of the Montana State University researchers. “Another is to use sensors we are currently developing, which provide a more bee-specific reflection signature from an elevated platform; in this scenario, the sensor would sweep over the nonflat field from above, being able to see all or most of the area.”

The researchers are working on a scheme to detect bees by the modulated scattering caused by their wingbeats. “We have built sensors to do this, and are working to characterize them and determine the optimal system that can be portable yet effective,” says Shaw.

REFERENCE

1. J. A. Shaw et al., Optics Express13(15) (July 25, 2005).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.