Great advances have been made at the Naval Research Laboratory (NRL) in reducing optical losses of infrared-transmitting chalcogenide glass fibers using improved chemical purification and better fiber fabrication techniques. The losses are now low enough for practical applications that include laser-power delivery, chemical sensing, scanning near-field microscopy/spectroscopy, and optical amplifiers and switches.

Glass preparation

Chalcogenide glasses are based on the chalcogen elements sulfur (S), selenium (Se), and tellurium (Te) with the addition of other elements such as germanium (Ge), arsenic (As), and antimony (Sb) that result in the formation of stable glasses. Chalcogenide glasses are melted directly in quartz ampoules using chemicals purified through distillation/sublimation. Typical melt temperatures range from 600°C to 900°C, depending upon composition. The liquids are quenched and the glass rods are annealed around the appropriate glass-softening temperatures. The optical fibers are fabricated by the double-crucible (DC) process, which enables adjustments to be made to the ratio of the core versus clad diameters during fiber drawing by independent pressure control above each melt.1 Therefore, both multimode and single-mode fibers can be drawn with relatively few processing steps.

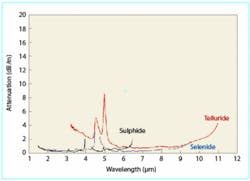

The optical-loss spectrum varies for different types of chalcogenide glass fibers and the practical applications dictate the type of fiber to be used (see Fig. 1).To date, sulfide-based fibers have received the most attention at NRL because of their low optical-loss values of only 0.1 to 0.2 dB/m in fiber lengths of about 500 m. These losses are sufficient for most applications, considering that relatively short fiber lengths (1 to 10 m) are typically used.

Applications

As their optical losses decrease, chalcogenide glass fibers are being used at NRL in a number of military and industrial applications.

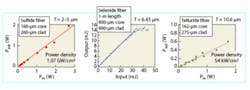

FIGURE 2. High-power laser energy can be transmitted through different types of chalcogenide optical fibers, depending upon the wavelengths required for the target application. The upper limit in each case was due to the maximum available power or pulse energy from the laser.

Laser-power delivery is an important application, allowing delivery of high-power laser energy through optical fiber for industrial welding, cutting, and medical surgery, as well as for military applications including anti-aircraft missile defense. Small-core-diameter (less than 200 µm) fibers are capable of transmitting continuous-wavelength (CW) laser power densities of at least 125 kW/cm2 at 5.4 µm (sulfide fiber) and 54 kW/cm2 at 10.6 µm (telluride fiber) without damage (see Fig. 2).2

Pulsed laser-power delivery in sulfide fibers has also been demonstrated by NRL at input peak power density of at least 1.07 GW/cm2 with no fiber damage for up to 1.5 × 107 pulses.3 This remarkable power handling capability is achieved by careful control of fiber polishing to prevent end-face surface damage.

Delivery of energy from a medical free-electron laser (MFEL) operating between 2 and 10 µm has also been demonstrated using chalcogenide fiber.4 It has been shown that in certain cases, surgery at 6.1 and 6.45 µm leads to less denatured tissue and scarring than with conventional erbium:yttrium aluminum garnet (Er:YAG) lasers operating at 2.94 µm. Successful demonstration of almost 18 mJ of output at 6.1 µm and 12 mJ at 6.45 µm has been achieved using large-core-diameter (800 µm) sulfide and selenide fibers, respectively.4 Antireflection coatings are expected to improve the transmission by reducing the reflection loss due to the high index of these materials (n of approximately 2.4). There is potential for applications involving laser machining of numerous materials and biological samples, by tuning the wavelength and transmission of the laser power through chalcogenide fibers to remote areas.

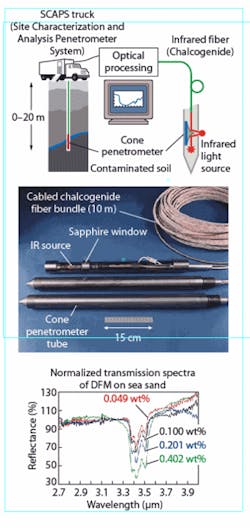

Chemical sensingor remote detection and identification of most molecular species due to their IR absorption “fingerprints” can be achieved by using chalcogenide fibers in fiberoptic chemical-sensor systems. For example, an optical-fiber-based reflectance probe has been developed at NRL to detect contaminants in soil (see Fig. 3).5 The detection was accomplished with the probe deployed in a cone penetrometer system and tested in the field. Detection limits of 130 ppm of marine diesel fuel (DFM) in sea sand have been demonstrated using a 20-m length of cable.

Condition-based maintenance (CBM) is becoming increasingly important in industrial applications and uses the approach, “if it isn’t broken, don’t fix it.” A fiberoptic dipstick probe, for example, could potentially monitor the quality of oil in small and large engines and consequently save large amounts of money in preventing unnecessary oil changes in the military and civil sector.

In the medical area, a chalcogenide fiber probe has been used to show the spectral differences between various tissues and organs in biomedical samples from chickens, sheep, and mice. Chalcogenide fibers have also shown utility for tissue evaluation and early detection of cancer. In contrast to conventional medical techniques in which large portions of tissue are cut out of the body and sliced into sections before a process such as Fourier transform IR (FTIR) spectroscopic analysis is used, a flexible optical fiber imaging approach is minimally invasive.

FIGURE 3. A cone penetrometer system using chalcogenide fiber can be used for the in-situ detection of contaminants and water in soil. A chalcogenide fiber is connected to a headend optical analysis system (top and center), and is inserted into the soil to be tested. The IR signals reflected from the soil and transmitted through the fiber to the FTIR in the truck are used to identify the contaminants (bottom).

Near-field microscopy is benefiting from the demonstration of sub-diffraction-limited resolution in the IR using high-quality single-mode and multimode chalcogenide fiber-tapered tips, whereby 20-nm topographic resolution and about 200-nm optical resolution have been obtained with NRL fibers for a variety of samples, including polycrystalline diamond, pancreatic cells, biofilms and semiconductor samples.6 This is a promising technique for IR-imaging spectroscopy of semiconductor and biological samples with submicron resolution.

Nonlinear effects

Nonlinear effects of chalcogenide optical fibers make possible a variety of new applications. The polarization (P) induced in a medium by an intense beam of light consists of both a linear response and a nonlinear response: P = εo (χ1E + χ2E2 + χ3E3 + …), where χ3 is the third order susceptibility, sometimes referred to as the third-order nonlinearity.Glasses possessing high third-order nonlinearities are required for ultrafast switching in compact time-division-multiplexing (TDM) telecommunications systems.

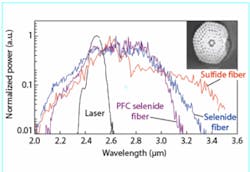

FIGURE 4. Supercontinuum generation is possible in small-core chalcogenide fibers. When pumped by a laser (spectrum shown within graph), a supercontinuum is generated for different types of chalcogenide fibers, including solid, glass-clad sulfide and selenide fibers as well as �holey� selenide photonic crystal fibers or PCFs (inset).

It is well established that the values of χ3 for chalcogenide glasses are about two orders of magnitude larger than that of silica.7 More recently, glasses have been reported with nonlinearities approaching values 1000 times greater than that of silica, bringing closer to reality the potential for compact and integrated all-optical switches.8 For example, a 10-cm device can induce a π-phase change to light signals using 100 MW/cm2 if the value for n2 (the third-order nonlinearity expressed as the nonlinear index) is 300 times higher than that of silica. Assuming that losses of 10% can be tolerated, this relates to a figure of merit (n2/β) of 5 (where β is the total loss). The figure of merit value for a selenide glass is actually 11, which means that the device length can be reduced to 3 cm and losses are reduced to only 3%. Experimentally, self-phase modulation corresponding to a π-phase change has been demonstrated in a 1-m length of small-core selenide fiber with losses of about 0.7 dB/m at 1.55 µm.9 The estimated value of n2 is about 850 times higher than silica, and is a record high value of n2 for any fiber device.

Supercontinuum generation

Supercontinuum generation has been demonstrated for the first time between 2 and 3 µm in NRL small-core sulfide and selenide fibers as well as photonic-crystal selenide fibers (see Fig. 4).10 One-meter lengths of fiber were pumped with a Ti:sapphire laser at 2.5 µm using 100-fs pulses with power levels of 100 pJ per pulse. The sulfide and selenide fibers had a 7-µm core diameter, while the photonic-crystal fiber had a 10-µm core diameter.

Raman amplification has also been demonstrated in small-core selenide fiber.11 More than 20 dB of gain in a 1.1-m length of fiber pumped by a nanosecond pulse of approximately 10.8-W peak power at 1.50 µm has been observed. The peak of the Raman gain was shifted by approximately 230 cm-1 to 1.56 µm. The large Raman gain coefficient, estimated to be about 700 times greater than that of silica, coupled with the broad IR-transparency window of these fibers shows promise for development of selenide Raman fiber lasers and amplifiers throughout the IR .

In the near future

Progress made in reducing the optical losses of chalcogenide glass fibers has led to the recent licensing of fiberization technology from the NRL to CorActive High-Tech for commercial production of chalcogenide fibers.

With further improvements and as new glass compositions are developed, IR fiberoptics will become increasingly important and remote IR spectroscopy and imaging using flexible fibers will become practical for medical and military applications. Areas that will inevitably be explored include the fabrication of Bragg gratings in fibers and exploitation of the highly nonlinear optical properties of the IR glasses for telecommunications and IR applications. Commercially available high-quality, low-loss and high-strength single-mode and multimode chalcogenide fibers will improve the capabilities of existing technologies and will likely enable the emergence of new technologies.❏

ACKNOWLEDGMENTS

The authors would like to acknowledge Richard Slusher of Lucent Technologies.

REFERENCES

1. J. S. Sanghera et al., Proc.SPIE 2396, 71 (1995).

2. L. E. Busse et al., Laser Focus World32, 143 (1996).

3. I. D. Aggarwal et al., Proc. Diode Laser Tech. Rev., Albuquerque, NM (March 2-4, 1998).

4. L. B. Shaw et al., CLEO Tech. Digest39, paper CThM74 502 (2000).

5. G. Nau et al., Proc. SPIE2504, 291 (1995) and U.S. Patent 5,739,536.

6. J. S. Sanghera et al., Proc. SPIE3596, 178 (1999).

7. K. A. Richardson et al., Opt. Mats.10, 155 (1998).

8. J. M. Harbold et al., Optics Letters, 27, 119 (2002).

9. R. E. Slusher et al., JOSA-B21, 1146 (2004).

10. L. B. Shaw et al., Adv. Solid State Photonics Tech. Digest, paper TuC5, Vienna, Austria (Feb. 6-9, 2005).

11. P. A. Thielen et al., Optics Lett.28, 16, 1406 (2003).

JAS S. SANGHERA, ISHWAR D. AGGARWAL, LYNDA E. BUSSE, PABLO C. PUREZA, VINH Q. NGUYEN, and L. BRANDON SHAW are scientists in the Optical Materials Research Group, Optical Sciences Division Code 5606, Naval Research Laboratory, 4555 Overlook Ave. SW, Washington, D.C. 20375; FREDERIC H. KUNG is an engineer with the University Research Foundation, 6411 Ivy Lane, Suite 110, Greenbelt, MD 20770; FRANCOIS CHENARD is vice president for corporate development, CorActive High-Tech, 2700 Jean-Perrin, Suite 121, Quebec (QC), Canada G2C 1S9; e-mail: [email protected].