Rapid prototyping evolves into custom manufacturing

With new materials, more-efficient lasers, and faster computers, techniques such as selective laser sintering and direct metal deposition are producing parts, not just prototypes.

Since its introduction in the 1980s, rapid prototyping has evolved from a relatively simple modeling technique that allows design engineers to “test” their ideas in three dimensions to a sophisticated custom-manufacturing tool that may one day find its place alongside the copy machines at the local copy center or in the parts department at the local auto dealership. Over the past 20 years, rapid-prototyping processes have allowed designers to improve their products and shorten the time it takes to bring new products to market. Today the introduction of new materials and lower-cost systems are pushing these same processes out of the design lab and into the manufacturing world, where they are being used to create custom parts that are production, not just prototype, quality.

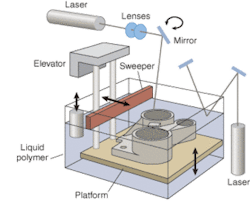

In SLA, ultraviolet energy-typically from a Nd:YAG, argon ion, or HeCd laser-activates a liquid photopolymer to solidify it into the desired 3-D model. Parts produced through SLA, which was patented in 1986, are known for their durability, feature detail, resolution, and surface quality.

Selective laser sintering typically uses a high-power CO2 laser to heat, melt, and fuse polymer or metal powders to create a solid, durable form for design communication and analysis (see Fig. 2). Developed in the 1980s at the University of Texas, selective laser sintering was patented in 1989 and first commercialized by a company called DTM (DTM was acquired by 3D Systems, Valencia, CA, in 2001).

Direct metal deposition is a laser-melting process that uses a powder nozzle to deposit metal powder onto existing tools to build the components layer by layer (see “High-power lasers enable metal-powder prototyping,” p. 131).

According to Terry Wohlers, an industry analyst based in Dearborn, MI, who publishes the Wohlers Report (a progress report on the rapid-prototyping, -tooling, and -manufacturing industries), more than 30 companies worldwide are now producing rapid-prototyping systems. The mainstream high-end devices, most of which are laser-based and sell for $100,000 to $500,000, are used to produce fairly rigorous prototypes and parts to study form, fit, and function. Nonlaser rapid-prototyping systems, which include fused deposition modeling, laminated object manufacturing, melted extrusion, and 3-D inkjet printing, sell for around $30,000 and offer an increasingly competitive alternative to SLS and SLA systems, especially for design visualization and communication applications.

But the laser-based methods are not expected to be displaced by these lower-cost systems because they have become well-established design engineering tools for industries ranging from automotive and aerospace to sporting goods, toys, electronic products, and medical devices and instruments. Companies such as 3D Systems offer laser and nonlaser systems and sell to a broad range of customers worldwide, including Apple Computer, AT&T, Eastman Kodak, Fiat, Ford, General Electric, General Motors, Hewlett Packard, IBM, Lockheed Martin, Motorola, NASA, and Tupperware. The applications are also wide-ranging; Burton Snowboards (Burlington, VT), for example, uses SLS to develop and rapidly test functional snowboard bindings. In the past, Burton outsourced its prototyped parts, with a turnaround of 14 to 16 weeks; with the Sinterstation HiQ SLS system from 3D Systems, the company can now develop binding prototypes in-house and test them on the snow within 48 hours of the initial concept.

“When rapid prototyping first started, it enabled us to make parts that offered form and fit but no function,” said David Bourell, professor of mechanical engineering at the University of Texas (Austin) and vice chair of the university’s Laboratory for Freeform Fabrication. “You could generate a 3-D shape to look at and evaluate, but that was all. One of the main evolutions of this technology has been to produce parts with sufficient geometry and material properties so that these parts can actually serve a functional process.”

Moving into manufacturing

While the last few years have seen the development of new rapid-prototyping technologies and processes that overcome the geometry problem, the available materials have not had adequate properties to enable them to build production-quality parts. Instead the prototype served primarily as a pattern to create a mold that could then be cast into a functional metal part. Today, however, the advent of new materials and improvements in the lasers and other technologies that melt, mold, and cure them - along with a better understanding of the materials properties in a prototyping or production environment¿are opening up entirely new applications for rapid prototyping. In fact, responding to growing demand for affordable "one-off" parts that are more durable than prototypes but can still be produced quickly and efficiently, the same technologies and processes used in rapid prototyping are finding new application in the custom manufacturing of production-quality parts " a field now referred to as "rapid manufacturing."

"Historically, rapid prototyping has been used to take additive processes and CAD to make prototypes,¿ said Neil Hopkinson, a lecturer in the Rapid Manufacturing Research Group (RMRG) at Loughborough University (Leicsestershire, England). ¿We are using these same processes to make an end-use product, but we see rapid manufacturing as an entirely different discipline with a different set of challenges." In fact, Hopkinson and colleagues are preparing the first book dedicated to rapid manufacturing, with academic and industrial contributors from around the world. (Rapid Manufacturing: An industrial revolution for the digital age is due to be published by Wiley in August 2005.)

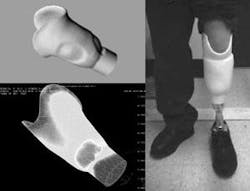

Research projects at the RMRG fall into one of three areas - design, processes/materials, and management - that often overlap. One current project involves the study of bespoke engineering to create a custom seat for a jet fighter pilot (see Fig. 3). The RMRG engineers are looking at how to design such a seat as a "one-off"; Hopkinson and his colleagues are also identifying the processes and parts that would be best suited to high-volume series manufacturing of a wide range of products. In addition, they are studying supply-chain issues with the idea that, should a part break at some point, rapid manufacturing could be used to fabricate a replacement for it right then and there.

Another RMRG project involves studying how termites make their mounds to see if their methods might be adapted to enable field-based fabrication of large buildings on the battlefield, or after an earthquake or other disaster. Researchers at RMRG are also working with elite athletes at Loughborough University in England to create optimized, customized sports equipment by scanning body parts and fabricating competitive-quality equipment, such as shoes, via rapid manufacturing. A key component of all of these projects is the materials research, according to Hopkinson.

"In terms of the future of rapid manufacturing, powders have the biggest future," he said. "At the moment, cured resins tend to cure over time, so the mechanical properties can change. If that can be overcome, there is a good future for the curing system, although I still expect powders to be the dominant material for rapid manufacturing."

Toward this end, RMRG researchers are also studying functionally graded materials - taking one type of powder, such as steel, and mixing it with, say, copper to make it 100% steel in one area, 100% copper in another, and a mix in between. This kind of applied materials research is important in helping to create new kinds of parts, such as a ceramic-coated metal jet-engine component, that can overcome reliability and durability issues experienced with conventional single-element materials.

"In terms of the parts we need to make, there are two aspects: we need to make them more durable, but also to make them repeatedly durable," Hopkinson said. "We need to be confident that we will get the same properties over and over. We are also interested in looking at effects of porosity and eliminating it but sometimes we quite like the porosity because a slightly porous part is actually lighter and offers some other attractive features. But we are just beginning to understand these issues."

Sometime in the next decade or so, Hopkinson anticipates that rapid manufacturing techniques (both laser and nonlaser) will find their way into the consumer market as well. And he is not alone; researchers at MIT's Center for Bits and Atoms have built miniature mobile manufacturing systems (dubbed 'fab labs) that combine a personal computer, laser cutter, 3-D scanner, drill, and numerically controlled X-Acto knife to create solid objects ranging from eyeglass frames and action figures to electronic devices such as radios and computers.1

"What we can see is these 3-D rapid-manufacturing machines being in schools and eventually down at the Kinko's or car dealership, to get replacement parts made right there," he said. 'Another possibility is to reverse-engineer a person¿s foot and look at making the sole of his shoe customized to him, and make it then and there. We have some work right now looking at making textiles by these same processes. But all of this requires a critical shift in thinking.

REFERENCES

1.B. Sterling, "The Dream Factory," Wired (December 2004).

High-power lasers enable metal-powder prototyping

Another emerging process in the field of rapid prototyping and rapid manufacturing involves the use of high-power lasers and metal powders to create end-use products. Since the mid-1990s, engineers have been working to advance rapid prototyping technologies for metal alloys, and their work is now paying off. According to industry analyst Terry Wohlers, at least a dozen companies now offer systems that produce metal prototypes layer by layer.

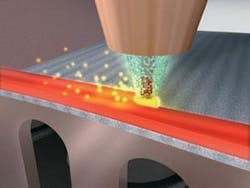

Foremost among these manufacturers is Trumpf (Ditzingen, Germany), which offers both direct laser forming (a stereolithography approach) and direct metal deposition (DMD) systems for the rapid manufacture of metal parts. Direct metal deposition is a generative laser-melting process that uses a high-power CO2 laser (2000¿6000 W) and a powder nozzle to deposit metal onto existing tools and components layer by layer in 3D (see figure). The powder nozzle sprays pure metal powder into the molten pool created by the CO2 laser beam on the component surface. Up to four modular powder feeders can be used at the same time. The amount of heat entering the workpiece is minimal. A sensor system with three CCD cameras monitors and controls the material deposition.

As a result of a melting process, the part is free of pores and cracks, the bond with the base material is extremely strong, and the material surface is completely sealed. The original tool loses none of its material properties and load-bearing capacity. Different powders can be mixed or alternately deposited in order to create customized layered constructions. In addition, by limiting heat input to a defined area, part distortion by the laser is minimized. Markets for this technology include tool and die, automotive, aerospace, medical, and offshore drilling¿all areas where there is much stress on the tooling or the components require extreme wear and corrosion resistance.

"DMD can be used for repair purposes and for refining or engineering of tools," said Robert Ganter, Project Manager at Trumpf. "The benefit of the laser is a very concentrated energy source; because we are bringing in a very low amount of energy compared to other processes (such as conventional welding or plasma spray), there is a very small and narrow heat-effect zone and superior bonding."