On May 16, 1960, Theodore Maiman built the world’s first laser at Hughes Research. As anyone who runs with the laser crowd knows, Maiman’s device was based on a flashlamp-pumped ruby crystal. The cylindrical ruby-laser rod, wrapped with a spiral flashtube and terminated with flat ends that defined its cavity, was, for a short time, the archetypal laser.

While the helium-neon laser, invented shortly afterward, quickly became an essential experimental aid, its low-power continuous beam could not even warm a lab technician’s hand. In contrast, the pulsed output of ruby lasers allowed even the early versions to pop a balloon-a harbinger of the laser as a materials-processing tool.

The first mention of a ruby laser in Laser Focus (Jan. 1, 1965) was as just that-a means to modify a substance, in this case metal. John Ready of Honeywell’s Research Center in Hopkins, MN, pursued approaches for calculating the “sometimes spectacular” heating effects produced when a ruby-laser beam struck metallic objects. His interests were microwelding and micromachining, as well as using lasers as plasma sources.

Watch out, lab rats

Early mentions in Laser Focus of ruby lasers for medical use include a laser retinal photocoagulator fabricated by Honeywell’s Ordnance Division and delivered to the Mayo Clinic (Rochester, MN), and a laser surgical tool developed by Raytheon and used at the Tufts New England Medical Center (Boston, MA). The latter laser produced 0.5- to 360-J pulses that Paul McGuff of Tufts exploited to destroy human melanomas and thyroid carcinomas implanted in the cheeks of mice. R. F. Heimberger of the Indiana University School of medicine, however, discovered that 250-J laser pulses applied to the heads of rats caused “explosive evaporation of tissue,” driving bone fragments into the rats’ brains. No mention was made of using the laser for rodent control.

The effect of ruby-laser pulses on rat foreheads was further explored by Edmund Klein, chief of dermatology at the Roswell Park Memorial Institute (Buffalo, NY); his intent, as reported in the April 15, 1965, issue of Laser Focus, was to illustrate the “potential health hazards resulting from current widespread industrial and medical use of lasers with increasingly higher energy and power levels.” Rats were struck in the head by pulses, either focused or unfocused, from a 100-J ruby laser; damage was moderate on the surface but more severe underneath, with fatalities occurring in 31 out of 41 animals. An interesting side effect was observed in the surviving rats: “The hair at the site of irradiation continued to grow, but was nonpigmented.”

The first laser rangers

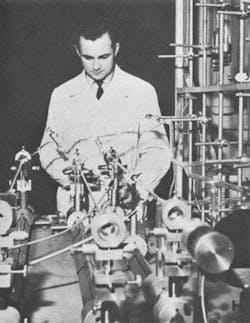

The pulsed nature of the ruby laser made it a natural for laser ranging, at least in 1965. An experimental prototype ruby-laser rangefinder was developed by the Laboratoire Central de Télécommunications (the French affiliate of ITT) to track a missile booster built for a European missile-launcher program (see figure). The prototype could detect signs at 1 mile, vehicles at 2.1 miles, and a flat white wall at 7.2 miles. A Q-switched ruby laser produced 50-ns pulses with 10- to 20-ns rise times, corresponding to about 3 m of travel. Commercial versions, one produced by TRG and the other by Hughes Aircraft and Barr & Stroud (Glasgow, Scotland), could range to 10,000 m on a clear day.

So where is the ruby laser now?

A clue lies in the inaugural issue of Laser Focus in January 1965. There, opposite the introductory page written by editor Bill Bushor, is the magazine’s first story-an applications piece on a laser air-to-ground beacon developed for NASA. The beacon, which emitted spherical waves to provide altitude and azimuth data, did not rely on the ruby laser, however. Instead, the flashlamp-pumped laser rod at the heart of the device was made of neodymium-doped yttrium aluminum garnet.

This Nd:YAG material, more efficient than ruby, more thermally stable, and able to run at higher pulse-repetition rates, has in the intervening years become the most widely used nonsemiconductor solid-state gain material. Easily and efficiently diode-pumped, Nd:YAG and other similar laser crystals are found in devices ranging from green laser pointers to multikilowatt industrial lasers, and have entirely displaced ruby for general high-power applications such as machining.

The ruby laser still found use, however-partly in pulsed holography, but mostly as a light source for medical and cosmetic uses such as removing tattoos, hair, freckles, and liver spots. Several companies manufactured ruby lasers for hair removal, for example the ruby laser produced up until recently by Palomar Medical Technologies (Burlington, MA). Many of these lasers are still in operation, helping to give the word “hirsute” its current negative connotation (apparently the procedure works better on humans than on rats).

But another type of laser-the alexandrite laser-has usurped this major role for the ruby laser. Not only is alexandrite tunable from 720 to 800 nm (a range that almost, but not quite, encompasses ruby’s 694-nm wavelength) but cosmetic alexandrite lasers are a fraction of the size of the older ruby devices, according to Rick Frost of Light Age (Somerset, NJ), a longtime manufacturer of alexandrite lasers. In addition, high-power diode-laser-based hair removal has become popular.

The ruby laser lives

The one advantage remaining for ruby over alexandrite for cosmetics is that its shorter wavelength is considered more effective for removing tattoos, and it better matches the absorption spectrum of melanin-containing pigmented skin. A laser for these purposes is being marketed by WaveLight Laser Technologie (Erlangen, Germany); unlike earlier cosmetic ruby lasers, this one has been shrunk to the size of a large suitcase. The GSI Group (formerly GSI Lumonics; Northville, MI) also makes a ruby laser for this purpose.

Ruby lasers are useful for high-speed photography and pulsed holography, for example, in a spinning-disk holographic device developed at North Dancer Labs (Shelburne, VT) that imaged projectile impacts at 500 kHz (see Laser Focus World, August 1999, p. 16). A ruby laser built by Continuum (Santa Clara, CA) and Physical Sciences (PSI; Andover, MA) was used to photograph munitions impacts at 1 MHz, although the follow-on laser, which had a 100-MHz capability, was an Nd:YAG (see Laser Focus World, June 2002, p. 40).

A ruby laser manufactured by InnoLas (Rugby, England) provides the two closely spaced pulses required for double-pulse holographic interferometry-a technique that quantitatively measures vibrations, changes in optical path length, and other transient shifts. The laser’s two 30-ns pulses can range in separation from 1 to 800 µs.❏

Inside Laser Focus

August 1965

■ Laser health hazards revisited

■ Revisions of laser warning sign reported

■ Laser beam transmits electric power

■ Effects of laser energy on brain and nerve tissues

■ NASA’s Gemini 7 laser voice communications project-A special report

■ Funds allocated for studying laser welding

■ Laser rangefinder delivered to Army, Navy

■ Laser system transmits voice ten miles

■ Report on soviet laser developments

■ Atmospheric particles measured via laser photography

■ Radiation source provides high-intensity light

■ Blue-green laser developed for hologram reconstructions

■ Some observations on biomedical lasers

■ More on high-energy laser medical unit

■ Laser communications predicted for Manned Mars Mission

■ External-mirror, solid-state laser operates CW

■ English laser rangefinder accurate over long distances

null