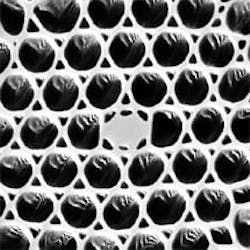

Conventional wavelength-tunable sources of femtosecond light pulses in the 1 to 1.3-µm range typically consist of large solid-state lasers with complex, high-precision cavities. Researchers at the Optoelectronics Research Centre (ORC; Southampton, England) have developed a much simpler version of such a source that is based on a ytterbium (Yb)-doped holey-fiber amplifier (see figure). The source is tuned through a phenomenon called soliton self-frequency shift (SSFS), in which the wavelength of the output pulses is a function of amplifier gain. Although fiber-based femtosecond pulse sources that use SSFS have previously been demonstrated, they have all operated at longer wavelengths; the ORC device is the first to approach the 1-µm wavelength.

The amplifier is seeded by a 1.06-µm-emitting Yb fiber laser—also developed at ORC—that is interesting in its own right. The seed laser, which is itself pumped with a 975-nm laser diode, includes a grating-based intracavity dispersion compensator, birefringent fiber, polarizers and waveplates for intra-cavity polarization control, and a semiconductor saturable absorber mirror to permit reliable self-start modelocking. The laser produces 60-pJ picosecond pulses (54-MHz repetition rate, 3 mW average power) that have a positive linear chirp and are compressible externally to 110 fs using either bulk gratings or holey fiber.

Approximately 20% of the seed-laser output is coupled into the 4.7-m-long holey-fiber amplifier, which is also pumped with 966-nm light from a diode master-oscillator power amplifier that has an output of 250 mW. The seed-laser pulses rapidly form solitons, which can be wavelength tuned by SSFS: by varying the pump power, the soliton peak power is adjusted, controlling the magnitude of SSFS and tuning the output pulse wavelength to wavelengths as long as 1.33 µm. The active amplifier medium is essential in that it not only permits the wavelength shifting of low-energy seed pulses, but also allows electronically controlled wavelength tuning via control of the amplifier gain. The distributed amplification process also results in a broader tuning range than is possible with passive tapered fiber devices.

Autocorrelation measurements show that the duration of the pulses exiting the amplifier remains approximately constant at 180 fs full width at half maximum. Using shorter pieces of the same holey fiber, the ORC researchers were able to produce light pulses as sort as 76 fs. Increasing the pump and seed pulse powers resulted in the generation of multicolor pulses separated in time as well as wavelength; some of these pulses reached a wavelength of 1.58 µm. According to David Richardson, one of the ORC researchers, the holey-fiber femtosecond pulse source could first find use in three-photon microscopy and, when frequency-doubled, as a source for biological and chemical applications in the red-green visible region.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.