Revised safety standards to benefit laser design and use

By Bryan A Tozer

The publication of Amendment 2 to IEC 60825-1 in January will prove to be an important event for the US laser industry. The IEC 60825 series of laser safety standards are accepted in most countries in the world as the basis of their laser safety requirements. The exposure limits in the IEC standard are also closely followed by the ANSI Z136.1 standards. The only serious exception is the statutory classification system of the US Federal Drug Administration, enforced through the Center for Devices for Radiological Health (CDRH), and even here we are promised changes to something close to IEC "soon."

Major changes

A complete redesign of the laser-hazard classification system, the introduction of new limits for exposure to picosecond pulses (based on recent research results) and changes to the time base for classification (which bring them more in line with research results on the human eye) will all result in relaxations in the upper power or energy limits of "safe" and "low risk" laser products (see table).

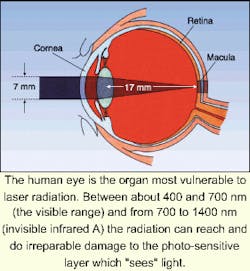

In the 400- to 1400-nm wavelength range, where the primary hazard is irreparable damage to the retina resulting in loss of sight, the exposure limits have been revamped to take into account the well-known "blue light" photochemical hazard at wavelengths between 400 and 600 nm and to better model the effects of eye movements on the retinal thermal hazard (see figure). These changes, which only take effect for exposure times greater than 10 s, have become necessary to deal with extended sources. Unfortunately, it has been found necessary to introduce dual limits, one for thermal hazard, one for photochemical hazard and a new time-dependent term "angle of acceptance" which must not be confused with "angular subtense."

Other changes which affect classification include an allowance to take into account the magnification effect on intermediate sources when a 50 mm measurement aperture is used for classification, and recognition of the group of lasers previously denoted by "Class 3B with not more than five times the AEL of Class 2 in the wavelength range from 400 to 700 nm," as a separate class denoted as Class 3R. The class has been expanded to include invisible lasers from 302.5 nm upwards with not more than five times the AEL for Class 1.

Effect of changes

The changes in the classification system, together with revisions of the maximum permissible exposure levels in accord with new understanding of the hazards, have resulted in significant relaxations for lower-power laser products used in a variety of applications.

As but one example, the IT industry, in particular, has entered a period of extraordinarily rapid growth in demand for capacity as a result of both the Internet and mobile phones. In optical-fiber technology, the development of dense wavelength-division multiplexing (DWDM) has resulted in a capability to transmit much higher laser powers through cables at 1550 nm. At the same time, the industry is developing open-beam transmission systems for short-distance communication. The industry will derive significant benefit in open-beam transmissions from the new Class 1M, which limits the power density (Wm-2) so that the maximum permissible exposure is not exceeded to the naked eye without setting an upper limit on total power.

The situation is less clear for optical fiber systems, however. These are governed by IEC 60825-2, which sets limits to permissible powers in fibers by reference to the existing class system. Working Group 5 of IEC/TC 76, which is responsible for IEC 60825-2, has recently met and recommended an interpretation of their standard in terms of the new classification system. This interpretation is still subject to international voting, but members of WG5 believe there is a good chance it will be endorsed. In summary, hazard levels are likely to be modified as appropriate:

Class 2 or 2M replaces Class 2, Class 1M or 3R replaces Class 3A, and Class k x 3A is deleted.

All informative annexes are temporarily deleted, as many of the calculated power levels in fibers are incorrect under the new amendment.

The user must employ Clause 9 and Table 10 of Amendment 2 to part 1 to calculate power levels and to assess hazard levels using the new system.

For hazard level 1M, at 1550 nm using standard single-mode fiber, the AEL is approximately 150 mW and is wavelength dependentthis represents approximately a three-fold increase on the current "hazard level 3A" in fibers. As before, the user must assess hazard level "under reasonably foreseeable fault conditions" (section 4.4.3 of IEC 60825-2).

These are just a few of the effects the adoption of this standard is likely to have on industry. Many more come to mind and no doubt many readers will be able to see avenues of opportunity opening for their own products or ideas. As understanding of the hazards of laser radiation increases and the range and variety of laser sources grows still further it will no doubt be necessary to further revise the standard to minimize the risk of human injury while avoiding unnecessary restraints on the uses of laser and LED sources where they offer a clear advantage over alternatives.

References

WORLD WIDE WEB ADDRESSES:

· International Electrotechnical Commission (IEC): www.iec.ch

· European Committee for Electrotechnical Standardisation (CENELEC): www.cenelec.org

STANDARDS:

· IEC 60825-1: (1993), Amendment 1 (1997), Amendment 2 (2001): Safety of laser products, Part 1. Equipment classification, requirements and user's guide.

· IEC 60825-2: (2000): Safety of laser products, Part 2. Safety of optical fiber communications systems.

· CENELEC EN 60825-1: (1994), amendment 1 (1996), amendment 2 (2001): Safety of laser products, Part 1.

· CENELEC EN 60825-2: (2000) : Safety of laser products, Part 2.

________________________________________________

In addition to being the convenor of WG5 and of IEC TC76, which is responsible for optical-fiber communications safety standards, BRYAN TOZER is managing director of Lasermet Ltd., 67 Portchester Road, Bournemouth BH8 8JX, England; e-mail [email protected].