PHOTONIC FRONTIERS: PHOTOVOLTAICS: Progress in the quest for photovoltaic power generation

Photovoltaics are starting to make economic sense for generating electricity in places like Hawaii, where sunlight is plentiful and conventional generation is costly, says Sarah Kurtz, reliability group manager at the National Renewable Energy Laboratory (NREL; Golden, CO). Another sign "that it has really arrived," she adds, is a report from market-analysis firm IHS (London, England) that says more than 30 GW of new photovoltaic power capacity was installed globally in 2012, and predicts the total will reach 40 GW in 2014.

Ironically, that success stems largely from the dramatic drop in solar cell prices that drove some high-profile manufacturers into bankruptcy. Now that prices have stabilized, the industry is getting down to the nitty-gritty of improving performance and lifetime, reducing production costs, and turning a profit. Some developers are looking to new markets, including powering mobile electronics. And research labs are in hot pursuit of a new class of materials to challenge the market domination of silicon.

The solar power problem

Photovoltaic power generation is appealingly clean and green, but it faces a big economic problem. The overall cost of photovoltaic generation is high and most of it has to be paid up front before a solar-power farm can feed its first watt of power into the grid. Conventional power plants are much cheaper to build, and much of their operating cost comes from fuel, which is not paid for until the power is generated.

Tax breaks and government subsidies fueled construction of the first round of photovoltaic power plants. With solar-cell prices now level, developers are squeezing system-level costs of delivering power to the grid, says Matt Feinstein, head of solar-systems research at Lux Research (Boston, MA).

The industry also is focusing on materials that offer the best combination of low cost, high efficiency, and long-term durability. "Crystalline silicon remains dominant, and it will for the foreseeable future," says Feinstein. With efficiency around 20%, a rooftop of silicon cells can generate enough electricity to power a home. Silicon is readily available, volume production makes it inexpensive, the technology is well understood, and it can withstand outdoor operation.

Two thin-film technologies, cadmium telluride and CIGS, copper indium gallium selenide (CuIn1-xGaxSe2), also could make an impact, Feinstein says. "Cadmium telluride is prominent because of First Solar (Tempe, AZ)," which has produced 7 GW of CdTe modules. However, some observers worry that CdTe might not be sustainable in the long term because cadmium is toxic and tellurium supplies are limited. Indium supplies are a concern with CIGS. Record efficiencies for both cited by NREL are close to 20%, with CIGS slightly higher (see Fig. 1); efficiency of mass-produced modules is lower.

Optimizing sunlight collection

Power generation depends on the arrangement of solar modules as well as the choice of photovoltaic material. Most power is collected by flat panels installed in sunny areas. Turning them on a single axis to track the sun across the sky can increase power generation during the day (see Fig. 2), and Feinstein says it has become almost standard on large solar power farms.An alternative is concentrating sunlight onto solar cells made of gallium arsenide (GaAs) or containing multiple junctions that absorb more of the solar spectrum and have reached efficiencies to 44.4% at 302 suns.1 These materials are costly, and focusing sunlight saves money by reducing the size required. Solar concentration also improves efficiency of multijunction and GaAs cells, which can withstand the resulting heat better then silicon.

Effective concentration requires two-axis tracking to keep the light focused onto the small solar cell as the sun moves in the sky, but two-axis tracking is complex and costly. Concentrated systems can be marginally competitive with flat panels if the available area is very limited or land is very expensive, says Feinstein. NREL sees both opportunities and challenges for concentrating technology.2

Reliability and the limits of plastic

Because upfront costs dominate solar generation costs, Kurtz says, "the only way solar power makes sense is if modules last a long time, and you have to be confident they will last when you buy them." Forty-year module lifetimes may not sound as exciting as new photovoltaic materials, but it's essential to make solar power economic. If modules last for decades, she says, 20 years of installing 30 GW each year will build total solar capacity to 600 GW, about 10% of today's total global electric generation capacity. NREL also is pushing reliability through the International PV Module Quality Assurance Task Force, which is developing ratings for module durability under various stresses and guidelines for factory inspections to maintain quality standards.

Poor durability and low efficiency have been key disappointments with polymer solar cells. "People thought polymers were much closer to technological readiness than they were," says Jonathan Melnick, a specialist in polymer electronics at Lux Research. It was easy to envision roll-to-roll mass production of low-cost solar cells, he says, but unless you master the complex technology, yields are poor and waste is high. Although record cell efficiencies exceed 10%, he says mass-produced polymer modules typically have only 3% efficiency. And their lifetimes are limited by the reactions of organic molecules with water and oxygen, especially in the high-energy environment of a solar panel.

High efficiency comes at a high price

The biggest problem for high-efficiency multijunction and GaAs cells is the high cost of the materials. So far, their applications largely are limited to solar concentration systems, which can use small cells to control costs, and to applications such as satellites where supplying maximum power per pound or square foot is crucial.

Alta Devices (Sunnyvale, CA) hopes to change that by making thin-film GaAs solar cells. The process starts with depositing active layers and the back metal contact on a GaAs wafer covered by a release layer that can be etched away, so the top metal contact and other coatings applied to the thin-film GaAs are left on top. "We end up with a very thin layer of GaAs and consume very little of the expensive material" because we can re-use the wafer, says Rich Kapusta, vice president of marketing at Alta. A bonus is that thin-film GaAs cells are more efficient than bulk GaAs, setting an NREL record for single-junction cells without concentrators with 28.8% efficiency. Alta also claims a record module efficiency of 24.1%.

Flexible sheets of thin-film GaAs can be made as large as the roof of a car, and a gram of the material can generate a watt of electricity, says Kapusta. He envisions embedding the films in modules usable as cell-phone cases or car roofs, where they could generate supplementary power to extend operation of mobile equipment. The thin-film cells also could power off-grid sensors and devices. "The technology is well-suited for concentrated light," says Kapusta, but Alta is focusing initially on using one-sun illumination for mobile devices.

A new class of materials

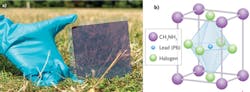

A new class of photovoltaic materials is coming on strong in the laboratory; a class of compounds called perovskites because they share the structure of the calcium titanate (CaTiO3) mineral (see Fig. 3). Photovoltaic action in organo-metallic halide perovskite semiconductors was first demonstrated in 2009. In the latest of a series of advances by several groups, three physicists at the University of Oxford (Oxford, England) reported efficiency above 15% in vapor-deposited thin films of CH3NH3PbI3-xClx in the September 19, 2013 Nature.3That puts the new material above polymers, amorphous silicon, and dye-sensitized solar cells. In a commentary, Michael D. McGehee of Stanford University (Stanford, CA) wrote that progress "suggests that the perovskites have extraordinary potential, and might elevate the solar-cell industry to new heights."4 Another attraction is that perovskites produce more than 1 V, more than the 0.7 V from a single silicon junction. Because their absorption peaks at shorter wavelengths than silicon, the two might be combined in a dual-junction cell to further increase efficiency.

The Materials Research Society is planning a special session on perovskites at its December 1-6, 2013, annual meeting in Boston. Some issues remain, McGehee wrote, including the presence of toxic lead and uncertainty about the long-term stability of the compound. However, further development could find less-toxic and perhaps more-efficient perovskite compounds.

Outlook

Any new material faces a big challenge in catching up to silicon, which has advantages of simplicity, durability, and a huge head start in development and infrastructure. Securing a solid future for photovoltaics requires both refining current technology to improve its cost, performance, and durability in the near future, and developing new materials for a new generation of technology.

REFERENCES

1. J. Hecht, "Photovoltaics takes small steps on journey to greater efficiency," Laser Focus World, 48, 12, 50–52 (Dec. 2012).

2. S. Kurtz, "Opportunities and Challenges for Development of a Mature Concentrating Photovoltaic Power Industry," NREL Technical Report NREL/TP-5200-43208.

3. M. Liu, M. B. Johnston, and H. J. Snaith, Nature, 501, 395 (Sept. 19, 2013); doi:10.1038/nature12509.

4. M. D. McGehee, Nature, 501, 323–324 (Sept. 19, 2013).

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.