BIOMIMETIC OPTICS: Coating that mimics firefly scales boosts LED light extraction

Jagged microscopic scales covering the surface of a firefly’s light-emitting abdomen make an excellent biomimetic light-extraction layer for LEDs, as researchers from Belgium, France, and Canada have discovered. With this knowledge, they then created an LED overlayer that substantially increased light extraction.1, 2 The researchers hail from the University of Namur (Namur, Belgium), European Synchrotron Research Facility (Grenoble, France), Université Catholique de Louvain (Louvain-la-Neuve, Belgium), and Université de Sherbrooke (Québec, QC, Canada).

The group determined that it was misfitting of the small, transparent scales that produced roughness and thus a microscale reflection-reducing coating.

The LED overlayer inspired by the firefly scales was arrived at by modeling the firefly scales, then optimizing for the high-refractive-index semiconductor material of a gallium nitride (GaN)-based LED (on which it was then applied). No redesign of the diode geometry was needed.

As shown by scanning electron micrographs, the actual makeup of the exterior of the firefly “lantern” consists of seven photonic substructures, from outside in: 1) longitudinal ridges in the cuticle the conduct light and scatter it out; 2) cuticle scales containing ribs on the order of 250 nm in spacing; 3) protruding edges on the scales that contribute to scattering; 4) a stack of about 30 plates below the scales with rod-like spacers about 250 nm apart in between the plates; 5) a layer mostly empty but for some fibers; 6) a solid, flexible membrane; and 7) the light-producing chamber made of granules about 1 μm in diameter.

Modeling the scattering

The computer model was based on a vectorial representation of the light waves (Maxwell’s equations), accounting for multiple scattering. A wavelength of 560 nm (yellow-green) was selected for the simulations. Each layer was modeled: In just one example, the misfit of scale edges of layer 3 allow many diffraction orders, so the model for that layer required convergence on the number of diffraction orders included.

The model showed an increase in light extraction of 55% for the firefly geometry over a flat control. The researchers discovered that the sharp edges of the jagged, misfit scales let out the most light. The finding was confirmed experimentally when the researchers observed the edges glowing the brightest when the cuticle was illuminated from below.

“We refer to the edge structures as having a factory roof shape,” says Annick Bay, a PhD student at the University of Namur who studies natural photonic structures, including beetle scales and butterfly wings. “The tips of the scales protrude and have a tilted slope, like a factory roof.”

The protrusions repeat approximately every 10 μm, with a height of approximately 3 μm. “In the beginning we thought smaller nanoscale structures would be most important, but surprisingly in the end we found the structure that was the most effective in improving light extraction was this big-scale structure,” says Bay.

Verifying via experiment

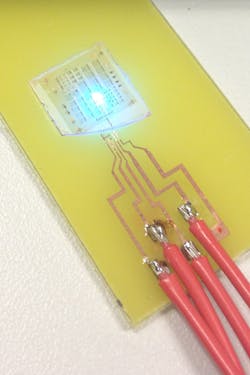

Nicolas André, a postdoctoral researcher at Université de Sherbrooke, deposited a layer of light-sensitive material on top of two GaN LEDs and then exposed sections on one of them with a laser to create the corrugated, jagged profiles. The higher index of the LEDs when compared to the firefly scales required a reduction of the height and width to 5 μm to maximize the light extraction.

A scatterometer was used to measure the absolute radiance of both coated LEDs over almost an entire hemisphere. The corrugations caused the total emitted optical power to increase by 33%, mostly due to diffusion at the sharp edges of the corrugations.

The Belgium-led team is the first to identify micrometer-scale photonic features, which are larger than the wavelength of visible light, but which surprisingly improved light extraction better than the smaller nanoscale features.

“The most important aspect of this work is that it shows how much we can learn by carefully observing nature,” says Bay.

REFERENCES

1. A. Bay et al., Opt. Exp., 21, 1, 764 (2013).

2. “An optimal light-extracting overlayer, inspired by the lantern of a Photuris firefly, to improve the external efficiency of existing light-emitting diode,” Opt. Exp., 21, S1, A179–A189 (2013).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.