For the first time, light is used to specifically design polymers

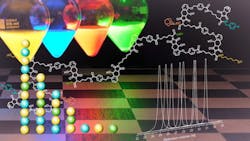

| Light-induced synthesis of customized molecules. Similar to a string of colored pearls, the building blocks are arranged at the desired positions. (Image: KIT) |

Chemists at Karlsruhe Institute of Technology (KIT; Karlsruhe, Germany) are now controlling the fabrication of precision polymers using photochemical reactions at room temperature. The method allows for the precise, planned arrangement of the monomers (individual chain links) along polymer chains of standard length.1 This was done using a "library" of six types of monomers, each with a different photoreactive molecule attached. The results were verified using matrix-assisted laser desorption/ionization–time-of-flight mass-spectrometry (MALDI–ToF).

"In many conventional processes, polymer chains of variable length are produced," says Christopher Barner-Kowollik of the KIT Institute for Chemical Technology and Polymer Chemistry (ITCP). "The building blocks are arranged randomly along the chain. We wanted to develop a light-induced method for polymer structuring which reaches the precision of nature." For example, proteins found in nature have an exactly defined structure.

"By controlling the structure of the molecule (the so-called sequence), properties of macromolecules can be controlled,” Barner-Kowollik says. “Sequence-defined polymers might also be used as molecular data and information storage systems.” Information could be encoded into the sequence of monomers, similar to the genetic information of DNA. The developers expect their method to become a tool for chemists, biologists, and materials scientists.

The new method was developed under the Collaborative Research Center 1176 “Molecular Structuring of Soft Matter” which is funded by the German Research Foundation (DFG) and coordinated by KIT. For the first four years, a budget of EUR 9 million is available to the Collaborative Research Center that started in January 2016.

Source: http://www.kit.edu/kit/english/pi_2016_165_macromolecules-light-to-design-precision-polymers.php

REFERENCE:

1. Nicolas Zydziak et al., Nature Communications (2016); doi: 10.1038/ncomms13672