High-resolution endoscope is thin as a human hair

Palo Alto, CA--Engineers at Stanford have developed a prototype single-fiber endoscope that improves resolution fourfold over existing designs.1 The advance could lead to needle-thin, minimally invasive endoscopes able to view features too small for today’s instruments.

The micro-endoscope was developed by a team under the direction of Joseph Kahn, professor of electrical engineering at the Stanford School of Engineering. The prototype can resolve objects about 2.5 µm in size; a resolution of 0.3 µm is easily within reach.

Related: Single multimode fiber is imager for in vivo applications

Related: Multimode optical fiber projects controllable light spots

Kahn and Olav Solgaard, also of Stanford, combined a multimode optical fiber with a miniature liquid-crystal spatial light modulator (SLM) and an adaptive computer algorithm developed by Kahn and his grad student, Reza Nasiri Mahalati) to unscramble the fiber's modes. Mahalati drew on seminal work in magnetic resonance imaging (MRI) done by John Pauly, another Stanford electrical engineer, who used random sampling to dramatically speed up image recording in MRIs.

SLM-related: Spatial modulation of femtosecond laser writes 3D waveguides in glass

SLM-related: Spatial-light-modulator hologram induces knot-shaped optical traps

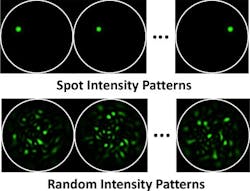

In the micro-endoscope's operation, the SLM projects random light patterns through the fiber into the body to illuminate the object under observation. The light reflecting from the object returns through the fiber; the reflected power is measured and the algorithm used to reconstruct an image.

Surprisingly, the endoscope resolves four times as many image features as the number of modes in the fiber. “This meant that, somehow, we were capturing more information than the laws of physics told us could pass through the fiber,” says Kahn. “It seemed impossible.”

The explanation is that the random intensity patterns mix the modes so that the the number of modes increases fourfold, allowing four times as much detail from the image to pass through the fiber.

Rigid now, but maybe flexible someday?

The main limiting factor of the working prototype at this point is that the fiber must remain rigid; bending a multimode fiber scrambles the image beyond recognition. Instead, the fiber is placed in a thin needle to hold it rigid for insertion.

Kahn is not the first to develop a single-fiber endoscope, but in boosting the resolution it is possible now to conceive of a fiber endoscope about 0.2 mm in diameter that can resolve about 80,000 pixels at a resolution of about 0.3 µm. Today’s best flexible fiber endoscopes, by comparison, are about 0.5 mm in diameter and can resolve roughly 10,000 pixels with a resolution of about 3 µm.

A rigid single-fiber micro-endoscope could enable myriad new procedures for microscopic imaging inside living organisms, ranging from analyzing neuronal cellular biology in brain tissue to studying muscle physiology and disease to the early detection of various forms of cancer.

But Kahn is hoping to someday create a flexible single-fiber endoscope. “No one knows if a flexible single-fiber endoscope is even possible, but we’re going to try,” he says.

REFERENCE:

1. Reza Nasiri Mahalati et al., Optics Express, Vol. 21, No. 1, p. 1656, 14 January 2013.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.