Philadelphia, PA--Research from the University of Pennsylvania has enabled "bulk" silicon to emit (http://www.laserfocusworld.com/articles/print/volume-42/issue-2/features/photonic-frontiers-silicon-photonics-closing-in-on-silicon-lasers.html) broad-spectrum, visible light for the first time, opening the possibility of using the element in devices that have both electronic and photonic components—especially in optical communications (https://www.laserfocusworld.com/optics/article/16548024/photonic-frontiers-integrated-photonics-photonic-integration-may-boost-computing-performance). Published in Nature Photonics, the research was conducted by associate professor Ritesh Agarwal and fellow colleagues in the Department of Materials Science and Engineering in Penn's School of Engineering and Applied Science.

Certain semiconductors, when imparted with energy, emit light; they directly produce photons, instead of producing heat. This phenomenon is commonplace and used in light-emitting diodes, or LEDs. Semiconducting materials—especially silicon—form the backbone of modern electronics and computing, but, unfortunately, silicon is an especially poor emitter of light and belongs to a group of semiconducting materials, which turns added energy into heat, making a true silicon laser not feasible. This makes integrating electronic and photonic circuits a challenge. "The problem is that electronic devices are made of silicon and photonic devices are typically not," Agarwal said. "Silicon doesn't emit light and the materials that do aren't necessarily the best materials for making electronic devices."

"People have tried to solve this problem by doping silicon with other materials, but the light emission is then in the very long wavelength range, so it's not visible and not very efficient and can degrade its electronic properties," Agarwal said. "Another approach is to make silicon devices that are very small, five nanometers in diameter or less. At that size you have quantum confinement effects, which allows the device to emit light, but making electrical connections at that scale isn’t currently feasible, and the electrical conductivity would be very low."

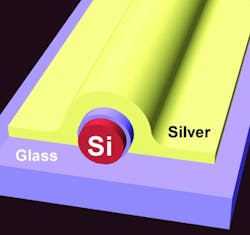

To get elemental, "bulk" silicon to emit light, Agarwal's team drew upon previous research they had conducted on plasmonic cavities (http://www.laserfocusworld.com/articles/print/volume-48/issue-10/world-news/plasmonics-enters-practical-wdm-switching-applications.html). In that earlier work, the researchers wrapped a cadmium sulfide nanowire first in a layer of silicon dioxide, essentially glass, and then in a layer of silver. The silver coating supports what are known as surface plasmons, waves that are a combination of oscillating metal electrons and of light. These surface plasmons are highly confined to the surface where the silicon dioxide and silver layers meet. For certain nanowire sizes, the silver coating creates pockets of resonance and hence highly confined electromagnetic fields—in other words, light—within the nanostructure.

Normally, after excitation the semiconductor must first "cool down," releasing energy as heat, before "jumping" back to the ground state and finally releasing the remaining energy as light. The Penn team's semiconductor nanowires coupled with plasmonic nanocavities, however, can jump directly from a high-energy excited state to the ground state, all but eliminating the heat-releasing cool-down period. This ultra-fast emission time opens the possibility of producing light from semiconductors such as silicon that might otherwise only produce heat.

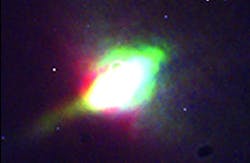

In their latest work, the group wrapped pure silicon nanowires in a similar fashion, first with a coating of glass and then one of silver. In this case, however, the silver did not wrap completely around the wire as the researchers first mounted the glass-coated silicon on a separate pane of glass. Tucking under the curve of the wire but unable to go between it and the glass substrate, the silver coating took on the shape of the greek letter omega while still acting as a plasmonic cavity.Critically, the transparent bottom of the omega allowed the researchers to impart energy to the semiconductor with a laser and then examine the light silicon emitted. Even though the silicon nanowire is excited at a single energy level, which corresponds to the wavelength of the blue laser, it produces white light that spans the visible spectrum. This translates into a broad bandwidth for possible operation in a photonic or optoelectronic device. In the future, it should also be possible to excite these silicon nanowires electrically.

"If you can make the silicon emit light itself, you don't have to have an external light source on the chip," Agarwal said. "We could excite the silicon electrically and get the same effect, and we can make it work with wires from 20 to 100 nanometers in diameter, so it's very compatible in terms of length scale with current electronics."

SOURCE: University of Pennsylvania; http://www.upenn.edu/pennnews/news/penn-engineers-enable-bulk-silicon-emit-visible-light-first-time

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.