Non-toxic 3D-printed medical implants possible with riboflavin compound

Raleigh, NC--Another light-based 3D printing breakthrough uses a non-toxic material for medical implants and other devices. Researchers from North Carolina State University (NC State), the University of North Carolina at Chapel Hill (UNC) and Laser Zentrum Hannover (Hannover, Germany) have discovered that a naturally occurring compound can be incorporated into three-dimensional (3D) printing processes to create medical implants out of non-toxic polymers. The compound is riboflavin, which is better known as vitamin B2.

"This opens the door to a much wider range of biocompatible implant materials, which can be used to develop customized implant designs using 3D printing technology," says Roger Narayan, senior author of a paper describing the work and a professor in the joint biomedical engineering department at NC State and UNC-Chapel Hill.

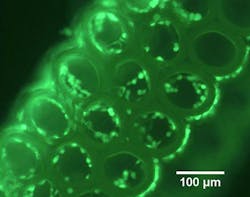

The researchers in this study focused on a 3D printing technique called two-photon polymerization, because this technique can be used to create small objects with detailed features--such as scaffolds for tissue engineering, microneedles, or other implantable drug-delivery devices.

Two-photon polymerization is a 3D printing technique for making small-scale solid structures from many types of photoreactive liquid precursors. The liquid precursors contain chemicals that react to light, turning the liquid into a solid polymer. By exposing the liquid precursor to targeted amounts of light, the technique allows users to “print” 3D objects.

Two-photon polymerization has its drawbacks, however. Most chemicals mixed into the precursors to make them photoreactive are also toxic, which could be problematic if the structures are used in a medical implant or are in direct contact with the body. But now researchers have determined that riboflavin can be mixed with a precursor material to make it photoreactive. And riboflavin is both nontoxic and biocompatible--it’s a vitamin found in everything from asparagus to cottage cheese.

The paper, "Two-photon polymerization of polyethylene glycol diacrylate scaffolds with riboflavin and triethanolamine used as a water-soluble photoiniator," is published online in Regenerative Medicine. Lead author of the paper is Alexander Nguyen, a PhD student in NC State and UNC-Chapel Hill's joint biomedical engineering program. The research was supported by National Science Foundation grant 0936110.

SOURCE: North Carolina State University; http://news.ncsu.edu/releases/wms-narayan-riboflavin/

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.