Nonvolatile liquid allows easy selectable-color luminescence for flexible displays

Tsukuba, Japan--A research team headed by Takashi Nakanishi, a principal researcher of the Organic Materials Group, Polymer Materials Unit of Japan's National Institute for Materials Science (NIMS), has developed a full-color tunable luminescent liquid material with high photostability based on anthracene, which is a general organic fluorescent dye.

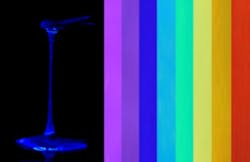

The team developed a blue-emitting liquid material that has a melting point of approximately -60 °C and is thermally stable up to about 300 °C. This material is a low-viscosity liquid that is blue-emitting with an absolute fluorescence quantum yield of about 55%. It is also photostable at least 5 to 10 times longer than commercially available anthracene dyes.

Because other luminescent dye molecules can be doped homogeneously in this liquid, it was found that full-color luminescence tuning is possible, assisted by up to 96% fluorescence resonance energy transfer (FRET) of dyes by single-wavelength (365 nm) excitation.

The nonvolatile liquid can be coated on the surface of various substrates, leading to organic multicolor devices with stable single-color excitation. A continuous active emitting layer can be maintained without breaking or interruption even when bent and folded, enabling foldable flexible displays.

The results were published in the online edition of Nature Communications.

Source: http://www.nims.go.jp/eng/news/press/2013/06/p201306050.html

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.