Graphene fluorescent quantum dots can be extracted cheaply from coal, resist photobleaching

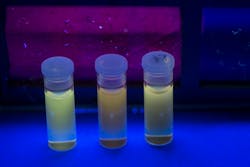

Houston, TX--Rice University researchers have developed simple ways to reduce three kinds of coal into graphene quantum dots (QDs), one carbon atom thick and 2 to 20 nm in size (depending on the coal source), with their band gap depending on their size.1 The graphene QDs can be used in place of other QD types for fluorescence-based sensing and imaging, photovoltaics, and other existing QD-based applications.

Related: Rice University’s fluorescent nanotube paint reveals mechanical strain

Breaking domains apart

Though researchers at another Rice lab found a way last year to make graphene QDs from relatively cheap carbon fiber, coal promises greater quantities of graphene QDs made even cheaper in one chemical step, says Rice chemist James Tour. “We wanted to see what’s there in coal that might be interesting, so we put it through a very simple oxidation procedure." This involved crushing the coal and bathing it in acid solutions to break the bonds between the graphene domains.

Different types of coal produce different types of dots. Graphene QDs were derived from bituminous coal, anthracite, and coke, a byproduct of oil refining.

The types of coal were each sonicated in nitric and sulfuric acids and heated for 24 hours. Bituminous coal produced graphene QDs between 2 and 4 nm wide; coke produced graphene QDs between 4 and 8 nm in size; and anthracite resulted in stacked structures from 18 to 40 nm in size with small, round layers atop larger, thinner layers. (Just to see what would happen, the researchers treated graphite flakes with the same process and got mostly smaller graphite flakes.)

Tour notes that the dots are water-soluble, and early tests have shown them to be nontoxic. This offers the promise that graphene QDs may serve as effective antioxidants. Testing in the lab of Rice chemist Angel Marti showed that graphene QDs resist bleaching for hours. “One of the problems with standard probes in fluorescence spectroscopy is that when you load them into a cell and hit them with high-powered lasers, you see them for a fraction of a second to upwards of a few seconds, and that’s it,” says Martí. “They’re still there, but they have been photobleached.”

Very low cost

“Graphite is $2000 a ton for the best there is, from the U.K.,” says Tour. “Cheaper graphite is $800 a ton from China. And coal is $10 to $60 a ton. Coal is the cheapest material you can get for producing graphene QDs, and we found we can get a 20% yield. So this discovery can really change the quantum-dot industry.”

Source: http://news.rice.edu/2013/12/06/coal-yields-plenty-of-graphene-quantum-dots/

REFERENCE:

1. Ruquan Ye et al., Nature Communications (2013); doi: 10.1038/ncomms3943

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.