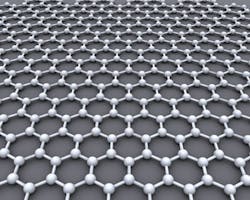

Max Planck team demonstrates that graphene can lase

Munich and Stuttgart, Germany and Harwell, England--Population inversion, and therefore laser action, has been demonstrated in graphene by Isabella Gierz and her colleagues at the Max Planck Institute for the Structure and Dynamics of Matter, together with researchers from the Max Planck Institute for Solid State Research (Stuttgart) and the Central Laser Facility (Harwell). The discovery is especially interesting because graphene lacks a classic semiconductor bandgap. (Note: researchers at Iowa State University in Ames, IA have previously detected broadband optical gain occurring in graphene, determining this by measurements showing negative absorption in the material.)

Although the forbidden band in graphene is infinitesimal, “the electrons in graphene behave similarly to those of a classic semiconductor,” says Isabella Gierz. To a certain extent, graphene could be thought of as a zero-bandgap semiconductor. Because of the absence of a bandgap, the population inversion in graphene only lasts for around 100 fs. “That is why graphene cannot be used for continuous lasers, but potentially for ultrashort laser pulses,” notes Gierz.

Terahertz-radiation amplification

Such a graphene laser could be used to amplify terahertz radiation. To date, terahertz radiation has usually been produced using comparatively inefficient nonlinear optical processes; in addition, the available wavelength range is often limited by the nonlinear material used. The recent findings indicate that graphene could be used for broad bandwidth amplification of arbitrarily long wavelengths, say the researchers.

The electrons in the graphene were excited using IR laser light; then the scientists used photoemission spectroscopy to demonstrate the occurrence of population inversion. In the spectroscopic techniques, ultrashort UV light pulses forced electrons out of the sample and their energy and angle of exit were measured. The resulting data established the energy distribution of electrons in the material (time resolution is achieved by delaying the arrival time of the UV probe pulse with respect to an arbitrary excitation pulse).

The graphene was produced by the scientists through thermal decomposition of silicon carbide. According to Gierz, this procedure can also be used to make a graphene laser, since silicon carbide is transparent and will not interfere with terahertz radiation. However, the physicist admits that a lot of development work remains to produce a graphene laser.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.