Cause of LED efficiency droop experimentally pinpointed at last

Santa Barbara, CA--LED efficiency droop is an effect that causes LEDs to be less efficient (sometimes much less) at higher currents. As a result, world-record LED efficiencies—and in particular, efficacies (lumens per watt) of visible gallium nitride (GaN)-based LEDs—all tend to be at impractically low drive currents. Now, researchers at University of California, Santa Barbara (UCSB) and the École Polytechnique (Palaiseau, France), have conclusively identified Auger recombination as the cause of LED efficiency droop. Until now, scientists had only theories.

This could all change now that the cause of LED efficiency droop has been explained, say researchers James Speck and Claude Weisbuch of the Center for Energy Efficient Materials at UCSB, an Energy Frontier Research Center sponsored by the U.S. Department of Energy.

In 2011, UCSB professor Chris van de Walle and colleagues theorized that a complex nonradiative process known as Auger recombination was behind droop in GaN-based LEDs. In Auger recombination, injected electrons lose energy to heat by collisions with other electrons rather than emitting light.

Related: LED efficiency puzzle solved by UC Santa Barbara theorists

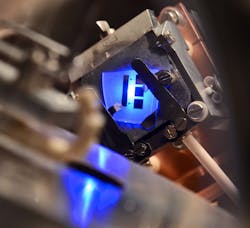

A definitive measurement of Auger recombination in LEDs has now been accomplished by the UCSB and École Polytechnique group. In the experiment, an LED with a specially prepared surface permitted the researchers to directly measure the energy spectrum of electrons emitted from the LED. The results unambiguously showed a signature of energetic electrons produced by the Auger process.

The results of their work are to be published in the journal Physical Review Letters. A similar version of the accepted manuscript can be found at http://arxiv.org/abs/1304.5469.

“This was a very complex experiment—one that illustrates the benefits of teamwork through both an international collaboration and a DOE Energy Frontier Research Center,” says Weisbuch, who is both a professor of materials at UCSB and a faculty member at the École Polytechnique. The work was funded by the UCSB Center for Energy Efficient Materials, an Energy Frontier Research Center of the US Department of Energy, Office of Science. Additional support for the work at École Polytechnique was provided by the French government.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.