Stretched germanium becomes gain material for integrated-photonics laser

Zurich, Switzerland--Researchers from ETH Zurich, the Paul Scherrer Institute (PSI; Villigen, Switzerland), and the Politecnico di Milano (Milan, Italy) have jointly developed a manufacturing technique to turn the semiconductor germanium (Ge) into a laser gain medium: stretching it to place it under mechanical strain.1

Related: Ge-on-Si laser will integrate with optoelectronics

Related: Leti demonstrates CMOS-compatible laser source coupled to silicon waveguide

Related: 'On-silicon' engineered substrates speed photonic device development

Related: Optical technologies scale the datacenter

"With a strain of 3%, the material emits around 25 times more photons than in a relaxed state," says Martin Süess, a doctoral student at ETH Zurich. "That’s enough to build lasers with," adds his colleague Richard Geiger, also a doctoral student at ETH Zurich.

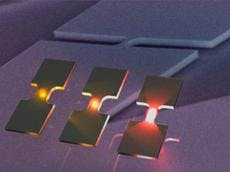

High tension through microbridges

To stretch the Ge, the researchers use the slight tension generated in Ge when it evaporates on silicon, strengthening this prestrain with so-called microbridges. They create exposed germanium strips, which remain attached to the silicon layer at both ends, an score the strips in the middle on both sides. The two halves of the strip thus remain connected solely by an extremely narrow bridge, where the strain of the germanium grows so large that laser action becomes possible.

"The tensile strain exerted on the germanium is comparable to the force exerted on a pencil as two lorries pull upon it in opposite directions," says Hans Sigg, the project manager at the PSIs. The material properties of Ge change because the strain enables the electrons to reach energy levels favorable for photon generation.

To create optical interconnects between and within computer chips, light sources are needed that are both very small and made of a silicon-compatible material (such as Ge). Silicon itself cannot be made to emit laser light.

"Germanium is perfectly compatible with silicon and already used in the computer industry in the production of silicon chips," says Geiger. The researchers are currently fabricating a germanium laser with the new method.

REFERENCE:

1. Süess M. J. et al., Nature Photonics (2013) Published online 14 April 2013. doi:10.1038/nphoton.2013.67.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.