Electrochemical strain microscopy at ORNL could help make fuel cells more practical

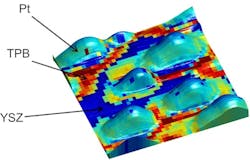

Oak Ridge, TN--A variant of electrochemical strain microscopy developed by researchers at the Oak Ridge National Laboratory (ORNL) may help cost the high cost of fuel cells.1 The technique allows them to examine the dynamics of oxygen reduction and evolution reactions in the materials for fuel cells with sub-10-nm resolution.

Platinum's high cost

The high cost of fuel cells based on large amounts of platinum catalyst has thus far limited the use of this efficient technology. In the ORNL technique, an electrocatalytically active scanning-probe tip measures surface displacements at the picometer scale, mapping electrochemical processes important to the operation of fuel cells. It is the oxygen-reduction reaction that controls the efficiency and longevity of the cell, yet exactly how and where the reaction takes place had not been probed because existing device-level electrochemical techniques are ill-suited to study the reaction at the nanoscale.

"If we can find a way to understand the operation of the fuel cell on the basic elementary level and determine what will make it work in the most optimum fashion, it would create an entirely new window of opportunity for the development of better materials and devices," said researcher Amit Kumar. Co-researcher Sergei Kalinin added that methods like electron microscopy had failed to capture the dynamics of fuel-cell operation because their resolution was effectively too high.

"When you want to understand how a fuel cell works, you are not interested in where single atoms are, you're interested in how they move in nanometer-scale volumes," Kalinin said. "The mobile ions in these solids behave almost like a liquid. They don't stay in place. The faster these mobile ions move, the better the material is for a fuel-cell application. Electrochemical strain microscopy is able to image this ion mobility."

Other electrochemical techniques are unable to study oxygen-reduction reactions because they are limited to resolutions of tens of microns.

Basic science, applied science, and technology

Kalinin made an interesting observation that incidentally highlighted the advanced state of the semiconductor industry (which has been closely pairing science and technology for decades). "There is a huge gap between fundamental science and applied science for energy-related devices like fuel cells and batteries," Kalinin said. "The semiconducting industry, for example, is developing exponentially because the link between application and basic science is very well established. This is not the case in energy systems. They are usually much more complicated than semiconductors and therefore a lot of development is driven by trial and error type of work."

Co-authors on the study are University of Heidelberg's Francesco Ciucci and Anna Morozovska from the National Academy of Science of Ukraine, whose theoretical analysis was critical in explaining the ESM measurements.

REFERENCE:

1. Amit Kumar et al., Nature Chemistry, published online 14 August 2011, doi:10.1038/nchem.1112

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.