Plasmonic metal-mesh sensor reveals what dust particles are made of

Columbus, OH--When irradiated by IR light, a metal film with a grid of micron-scale holes reveals the composition of dust particles sticking to it. The light creates surface plasmons on the grid; any material stuck in the holes leaves a unique signature on the IR spectrum. This allows researchers from Ohio State University to tell which specks of dust are organic, which are quartz, which are gypsum, and so on.1

Spectroscopic identification

James Coe and his group didn't set out to study dust. He and his team invented the metal-mesh sensor in 2003; early this year, the researchers coated the mesh with a ring of microscopic latex spheres to take a baseline measurement. The result should have been a spectrum unique to latex, but instead the spectrum carried the signature of several common minerals due to a single dust particle that had gotten inside the sensor.

They went on to test more dust particles: the 63 specks they identified were mainly irregular blobs containing bits of many different ingredients.

The most common ingredient of the dust particles was organic matter, says Coe, though the researchers can't yet say precisely what kinds of organic matter they found. They are about to do an in-depth analysis to find out.

Quartz was the second-most common ingredient. Both quartz and organic matter were found in more than half of the dust particles the researchers classified. Manmade chemicals from air pollution, fertilizers, and construction materials were also present in small amounts.

The result is a library of common dust components from the lab. Forty of the particles (63%) contained organic material. The most common mineral was quartz, which was present in 34 (54%) of the particles, followed by carbonates (17 particles, or 27%) and gypsum (14 particles, or 22%).

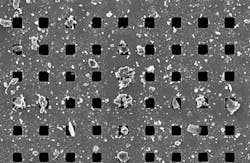

The metal-mesh sensor used in the test has a 12.6-micron-square lattice of 5-micron-square holes, and detects dust particles in the 3 to 5 micron size range.

Currently, Coe and his team are constructing computer algorithms to better analyze the mineral components and reveal details about the organic components.

REFERENCE:

1. Katherine E. Cilwa et al., Journal of Physical Chemistry C (2011), p. 16910; DOI: 10.1021/jp205383h.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.