FREQUENCY COMBS: Mid-IR frequency combs use microresonator and thulium-fiber designs

Interest in the mid-infrared (mid-IR) spectral region continues to grow for applications in molecular fingerprinting, IR countermeasures, near-field microscopy, and materials processing. Recognizing the importance of metrology tools to further boost mid-IR capabilities, research groups in Europe and the US have used two different methods to generate mid-IR frequency combs. Microresonator-based frequency combs—spanning more than 10 THz around the 2.5 µm wavelength—were developed for the first time by researchers from the Max Planck Institute for Quantum Optics (Garching, Germany), École Polytechnique Fédérale de Lausanne (EPFL; Lausanne, Switzerland), Menlo Systems GmbH (Martinsried, Germany), Ludwig-Maximilians University (Munich, Germany), and the Institut des Sciences Moléculaires d’Orsay (Orsay, France).1 And researchers from IMRA America (Ann Arbor, MI) and Stanford University (Stanford, CA) have developed the first self-referenced thulium-fiber-based mid-IR frequency combs that span 260 THz around the 2 µm window.2 Because the designs are different, each offers unique attributes that target particular optical-frequency metrology applications.

Microresonator-based combs

Mid-IR frequency combs are typically produced by frequency conversion of near-IR radiation via nonlinear processes that limit their spectral bandwidth and power-per-comb-line. By using an alternative method for the first time—third-order Kerr nonlinearities in ultrahigh-Q whispering gallery mode microresonators—frequency comb generators that are compact and broadband with widely spaced high-power-per-comb-line are possible.

Crystalline magnesium-fluoride (MgF2) microresonators with diameters ranging from 100 µm to 1 mm and quality factors Q of approximately 109 are pumped by a continuous-wave (CW) optical parametric oscillator tunable between 2.4 and 2.5 µm. The several hundred milliwatts of power are delivered by a tapered-fiber waveguide that also couples the frequency components out of the microresonator and back into the optical-fiber-based setup (see Fig. 1). The microresonator stays thermally self-locked to the pump laser because the temperature coefficient of the refractive index and the thermal expansion coefficient of the MgF2 material are both positive, creating frequency comb lines directly from the CW pump laser through four-wave-mixing (FWM) processes.

For a 700-µm-diameter microresonator (finesse 1.2 × 105) pumped with 600 mW of 2.45 µm light, an optical frequency comb centered around the pump wavelength with lines spaced by 108 GHz is generated that spans more than 200 nm or 10 THz.

“This simple approach holds promise to create mid-infrared combs across the entire transparency window of the material,” says postdoctoral researcher Christine Wang at the Max Planck Institute for Quantum Optics. “The microresonator design can generate large comb spacings between 10 and 100 GHz so that individual comb lines can be accessed. The high power per line may make our design suitable for selective frequency excitation and vibrational spectroscopy of dense media.”

Thulium-fiber-based combs

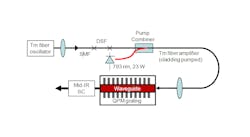

Unlike previous thulium (Tm) fiber oscillators with long pulsewidths that degrade coherence of the resultant supercontinuum, the IMRA and Stanford researchers developed a 100 fs level, nearly linear Tm oscillator/amplifier system that uses a periodically poled lithium-niobate (PPLN) crystal for both octave-spanning supercontinuum generation and carrier-envelope-offset (CEO) frequency sensing.

Modelocked laser pulses as short as 70 fs with average power 30 mW at 72 MHz generated by a Tm fiber oscillator are chirped in a positive-dispersion fiber and compressed by a 2-m-long, large-core-diameter (25 µm), cladding-pumped Tm amplifier fiber. The near-linear amplified pulses are then input to a PPLN waveguide designed to support wavelengths up to 4 µm. A parabolic input taper to the waveguide excites the lowest-order 2 µm mode, which propagates through an 18.5-mm-long quasi-phase-matched (QPM) grating (period 22.11 µm), leading to supercontinuum generation from 1350 to 2700 nm at the -40 dB level. The pulses are spectrally broadened as they propagate through the PPLN waveguide, primarily through a phase-mismatched second-harmonic-generation process. Once sufficient broadening has occured, spectral components around the fundamental, second harmonic, and third harmonic frequencies overlap, enabling direct observation of the carrier envelope offset frequency.“The thulium-fiber combs are well suited for precision and broad-bandwidth spectroscopy in the molecular fingerprint region,” says Stanford University graduate student Christopher Phillips. “Thulium-fiber comb technology is capable of generating phase-stable pulses at high power levels that will enable applications such as XUV comb generation and direct electron acceleration.”

REFERENCES

1. C.Wang et al., Conf.on Lasers and Electro-Optics (CLEO) postdeadline paper PDPA4 (May 2011).

2. C.Phillips et al., CLEO postdeadline paper PDPA5 (May 2011).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.