Rainbow polymer grating could lead to handheld multispectral imaging devices

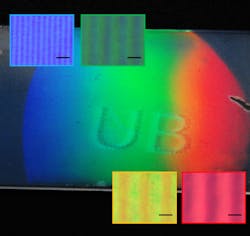

Buffalo, NY--A new polymer grating developed by engineers at the University at Buffalo (UB), The State University of New York, is rainbow colored when viewed from a single perspective, reflecting many different wavelengths of light. The polymer is fabricated in a one-step, low-cost method and could be used as a filter for handheld multispectral imaging devices that identify the "true color" of objects examined.

"The ease of producing the polymer could make it feasible to develop small devices that connect with cell phones to conduct multispectral imaging," said Qiaoqiang Gan, a UB assistant professor of electrical engineering and another member of the research team. "Our method is pretty low-cost, and because of this and the potential cell phone applications, we feel there is a huge market for improving clinical imaging in developing countries," Gan said.

The rainbow colors appear due to the surface geometry of the filter, and not by pigments; the same biomimetic principle that colors the wings of butterflies and peacock feathers. The work was reported on online Feb. 22 in Advanced Materials. The UB Office of Science, Technology Transfer and Economic Outreach (STOR) has submitted a provisional patent application detailing the production process to the U.S. Patent and Trademark Office.

To create the rainbow material, the creators sandwiched a photosensitive pre-polymer syrup between two glass slides. Next, they directed a laser beam through a curved lens placed above the pre-polymer solution. The lens divided and bent the laser beam into light of continuously varying wavelengths. As this light hits the solution, monomers in the solution began joining into polymers, forming a continuous pattern of ridge-like polymer structures. The resulting structure is a thin filter that is rainbow-colored when viewed under white light. The filter the researchers created was about 25 mm long, but the technique they used is scalable and different sized filters can be fabricated.

SOURCE: University at Buffalo; www.buffalo.edu/news/13214

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.