World's most stable laser created by NIST/JILA and German researchers

Boulder, CO--An international collaboration of scientists at NIST/JILA and a group at Physikalisch-Technische Bundesanstalt (PTB; Braunschweig, Germany), the German counterpart of NIST, has developed and tested the world's most stable laser, with frequency variation of no more than 2 parts in 10,000 trillion. As reported in Nature Photonics online, the achievement represents a new approach for constructing high-quality optical cavities that will bring more than an order of magnitude improvement over prior designs. The scientists say that in particular, the work will accelerate progress in development of optical clocks, which operate at frequencies more than 10,000 times higher than the approximately 9.2 GHz microwaves used as the basis of the current worldwide time standard.

In addition, the novel laser design is expected to usher in a new level of precision to research in gravitational wave detection on Earth and in space, and precision tests of relativity as well as fundamental physics research in cavity quantum electrodynamics and quantum optomechanics.

"The previous stability limit of about 2 × 10-16 was good," says study co-author Jun Ye of JILA and PML's Quantum Physics Division. "But it prevented us from exploring the full potential of modern optical atomic clocks where the atomic coherence time can be exceedingly long. The potential of pushing the laser stability better by an order of magnitude will allow us to realize atomic clocks that have unprecedented stability approaching 1 × 10-17 over 1 second."

"And it may be of intense interest to the communications industry, since our system was tested at a familiar telecomm wavelength of 1.5 micrometers." Research on ultra-stable lasers typically uses some kind of optical-cavity interferometer, comprising a spacer with mirrors at each end. That design severely restricts the range of optical frequency that can resonate in the cavity. By superimposing the cavity output beam on another highly controlled reference beam, the interference effects (periodic reinforcement "beats") can reveal stability with exquisite sensitivity. Such systems, however, have historically been subject to thermal fluctuations that alter the cavity dimensions, and hence reduce frequency stability.

"We addressed that problem in several ways," says Ye, who began to collaborate on the project in 2007 while visiting PTB in Germany on a grant from the Alexander von Humboldt Foundation. The German team was headed by Uwe Sterr and Fritz Riehle. Ye also recruited a student, Michael Martin, and a visitor in his lab, Lisheng Chen. "By far the most significant factor was our decision to substitute single-crystal silicon for the ultralow expansion glass (ULE) or fused silica customarily employed in the cavity mirrors and spacers."

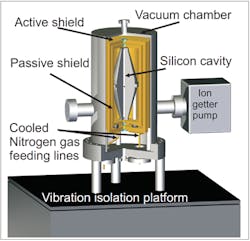

Single-crystal silicon has a coefficient of thermal expansion that approaches zero at 124 K, "so an all-silicon interferometer can be made insensitive to temperature fluctuations" at that point, the authors write in Nature Photonics. In addition, at 124 K the crystal has a much lower mechanical loss compared to conventional optical glass, and a much higher Young’s modulus. Both mechanical properties combine to minimize the fundamental thermal fluctuations. The group used extensive computer modeling to create a design that reduced the effects of environmental vibrations on the 21 cm long resonator, which they mounted in a vertical configuration after testing its response to external forces in all three dimensions. Finally, the German researchers devised a novel and simple cryostat design using evaporated liquid nitrogen gas as the coolant. The gas flows through superinsulated vacuum tubes to an outer heat shield, and careful control of the flow limits temperature deviations in the system to about 1 mK from the 124 K target.

The new all-silicon unit was tested for 24 hours against two of the best-performing conventional ULE-based optical cavity-stabilized lasers—one from JILA and one from PTB, with thermal noise variation in the range of 6 × 10-16 and 2 × 10-16 respectively. The results, Ye says, “show that the all-silicon system surpasses the performance of any other optical cavities ever reported.” As a long-term stable frequency reference, a preliminary test has shown that it is equivalent to the stability of a hydrogen maser at time intervals up to 1,000 seconds.

The scientists are already at work to improve those figures. Among other modifications, they will attempt to reduce feedback errors due to spurious amplitude modulation, suppress noise from the cryostat, and experiment with different optical coatings on the silicon mirrors. The very thin optical coatings now remain the only significant contribution to the thermal noise of the cavity and new approaches are already being investigated jointly with Markus Aspelmeyer's group at the University of Vienna.

SOURCE: NIST; www.nist.gov/pml/div689/new-ultrastable-laser.cfm

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.