Black-silicon solar cells capture infrared at double efficiency

Berlin, Germany--Photovoltaic (PV) solar cells convert three-quarters of the energy contained in the Sun‘s spectrum into electricity, yet the IR spectrum is entirely lost in standard PV cells. In contrast, black-silicon PV cells are specifically designed to absorb this part of the Sun‘s spectrum—and researchers at the Fraunhofer Institute for Telecommunications, Heinrich-Hertz-Institut (HHI) have recently succeeded in doubling their overall efficiency.

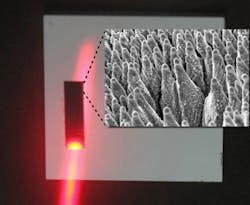

About a quarter of the Sun’s output is made up of IR radiation that cannot be converted by standard solar cells. However, black silicon absorbs more of the sunlight that hits it, including IR, and converts it into electricity. But how is this material produced? “Black silicon is produced by irradiating standard silicon with femtosecond laser pulses under a sulfur containing atmosphere,” explains Stefan Kontermann, who heads the research group “Nanomaterials for Energy Conversion“ within the Fraunhofer Project Group for Fiber Optical Sensor Systems. “This structures the surface and integrates sulfur atoms into the silicon lattice, making the treated material appear black.”

Changed fabrication, boost in IR efficiency

If manufacturers were to equip their solar cells with this black silicon, it would significantly boost the cells’ efficiency by enabling them to take advantage of the full spectrum of the Sun. The HHI researchers have recently doubled the efficiency of black silicon solar cells. “We achieved that by modifying the shape of the laser pulse we use to irradiate the silicon,” says Kontermann.

This enabled the scientists to solve a key problem of black silicon: In normal silicon, IR light does not have enough energy to excite the electrons into the conduction band and convert them into electricity, but the sulfur incorporated in black silicon forms a kind of intermediate level. By modifying the laser pulse that drives the sulfur atoms into the atomic lattice, researchers can change the positions that these atoms adopt in the lattice and change the height of their energy levels. “We used the laser pulses to alter the embedded sulfur in order to maximize the number of electrons that can climb up while minimizing the number that can go back down,” Kontermann notes.

Commercialization, spin-off

The researchers have built prototypes of black-silicon PV cells and their next step will be to try and merge these cells with commercial technology. “We hope to be able to increase the efficiency of commercial solar cells—which currently stands at approximately 17%—by 1% by combining them with black silicon,” Kontermann says. Their starting point is a standard commercial solar cell: The experts simply remove the back cover and incorporate black silicon in part of the cell, thereby creating a tandem solar cell that contains both normal and black silicon.

The researchers are also planning a spin-off to market the laser system, which will allow manufacturers to produce the black silicon themselves.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.