Printed photonic-crystal mirrors shrink size of on-chip lasers

Madison, WI--In the July 22, 2012 issue of Nature Photonics, electrical engineers at the University of Wisconsin-Madison (UW-Madison) and the University of Texas at Arlington (UT Arlington) describe a new laser for on-chip optical connections that could give computers a huge boost in speed and energy efficiency. At just 2 micrometers in height, the suface-emitting laser's vastly lower profile could make it cheaper and easier for manufacturers to integrate high-speed optical data connections into the microprocessors powering the next generation of computers.

Traditionally, edge-emitter lasers are considered as the candidate for on-chip optical links. But since mirrors are hard to form in such lasers and because the lasers occupy a large chip area, researchers have been challenged to find a practical way to monolithically integrate the mirrors on silicon chips.

The engineers say that 20-30 micron-tall surface-emitting lasers mounted on a 1.5 micon chip dwarf their silicon surroundings. "It sits tall on the chip, like a tower," says Zhengiang Ma, A UW-Madison professor of electrical and computer engineering. "That is definitely not acceptable." In addition, another challenge is integrating the lasers into silicon chips, as silicon itself is not an efficient light emitter.

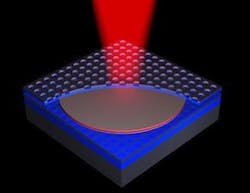

Ma and colleagues have collaborated to shrink on-chip lasers in recent years with funding from the U.S. Air Force Office of Scientific Research, Army Research Office and Defense Advanced Research Projects Agency. As a solution, the researchers propose replacing layers and layers of reflectors necessary in the traditional distributed Bragg reflector laser design with two highly reflective photonic crystal mirrors. Composed of compound semiconductor quantum well materials applied with a transfer printing process, each mirror is held in place with silicon nanomembranes, extremely thin layers of silicon.

One layer of photonic crystal is equal to about 15 to 30 layers of dielectric reflectors found in conventional lasers. As a result, manufacturers could fabricate 2 micron high lasers for data links with performance that could equal current designs. The printing process also takes place at much lower temperatures that conventional designs, improving the process.

Although the Internet backbone is composed mainly of fiber-optic links between countries, cities, and houses, the data moves over to slower metal connections and wiring as it travels from a regional hub to your house, your computer ,and eventually between the CPU cores within of the processor powering your machine. "In the future, you'll see a move to optical at each step," Ma says. "The last step is within the chip, module-to-module optical links on the chip itself."

Through Semerane Inc., a Texas-based startup, the engineers hope to implement their production process in functional on-chip photonic crystal membrane lasers that could eventually be part of the next generation high-speed computer processors.

SOURCE: University of Wisconsin-Madison; www.news.wisc.edu/20895

IMAGE:An artist's representation shows a proposed on-chip laser design, created via transfer printing of photonic crystal between layers of silicon nanomembranes. (Courtesy Hongjun Yang, University of Wisconsin-Madison)