In contrast to the Space Elevator concept, in which high-power continuous-wave lasers beam light to photovoltaic cells attached to a vehicle that rides into space on a cable at relatively slow 5 m/s speeds, beamed-energy propulsion (BEP) focuses a megawatt-level peak-power laser on a propellant onboard a next-generation nano-satellite launcher to boost a kilogram of payload into low-Earth orbit. While BEP technology advances over the years have been largely theoretical, researchers at Rensselaer Polytechnic Institute (Troy, NY) and the Instituto de Estudos Avançados (São José dos Campos, Brazil) are demonstrating airbreathing laser-thermal propulsion at hypersonic speeds in the laboratory for the first time.

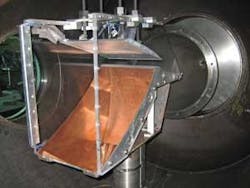

An 1800 MW maximum-peak-power CO2 laser (90 to 100 ns peak power pulse duration for a pulse approximately 1 µs long) is beamed to a “LightCraft” test fixture inside a hypersonic shock tunnel and focused using 2-D parabolic optics into the engine absorption chamber. Similar to the operation of a chemical-fueled scramjet (a supersonic ramjet or jet engine that depends on supersonic forward motion to compress the captured incoming air), the laser super-heated air expands rapidly to produce thrust. The experiment explores full-size-engine physics under simulated flight speeds of Mach 7 to 9, wherein the laser engine transitions from airbreathing into rocket mode at the top of the atmosphere. Contact Leik Myrabo at [email protected].