Livermore, CA--The National Nuclear Security Administration's National Ignition Facility (NIF) has set world records for neutron yield and laser energy delivered from laser-driven capsules to an inertial-confinement-fusion (ICF) target.

The neutron-yield record was set on Oct. 31, when the NIF laser fired 121 kJ of ultraviolet laser light into a glass target filled with a deuterium and tritium (DT) gas mixture. The shot produced approximately 3 x 1014 neutrons from DT fusion, the highest neutron yield to date by an inertial-confinement fusion facility.

Hohlraums and symcaps

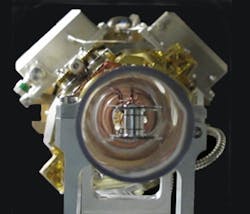

On Nov. 2, the team fired 1.3 MJ of ultraviolet light into a cryogenically cooled cylinder called a hohlraum containing a surrogate fusion target known as a symmetry capsule, or symcap. This was the highest-energy laser shot and was the first test of hohlraum temperature and capsule symmetry under conditions designed to produce fusion ignition and energy gain. Preliminary analysis indicated that the hohlraum absorbed nearly 90% of the laser power and reached a peak radiation temperature of 300 eV, making it the highest X-ray drive energy ever achieved in an indirect-drive ignition target.

In the Oct. 31 "neutron calibration" shot, NIF's lasers were fired directly onto a DT-filled glass target, as opposed to the indirect-drive geometry used in NIF's DT and tritium, hydrogen, and deuterium (THD) experiments. The purpose of the shot was to calibrate and test the performance of NIF's extensive neutron diagnostic equipment.

The capsule used in the Nov. 2 symcap experiment has the same 2-mm-outer-diameter doped shell as an ignition capsule, but replaces the DT fuel layer with an equivalent mass of material from the outer shell to mimic the capsule's hydrodynamic behavior. Achieving a highly symmetrical compression of the fuel capsule is a key requirement for NIF to achieve its goal of fusion ignition.

The experiments followed closely on the heels of NIF's first integrated ignition experiment on Sept. 29, which demonstrated the integration of the complex systems required for an ignition campaign including a target physics design, the laser, target fabrication, cryogenic fuel layering and target positioning, target diagnostics, control and data systems, and tritium handling and personnel and environmental protection systems. In that shot, 1 MJ of ultraviolet laser energy was fired into a cryogenically layered THD capsule tailored to enable the most-comprehensive physics results.

"The results of all of these experiments are extremely encouraging," said NIF director Ed Moses, "and they give us great confidence that we will be able to achieve ignition conditions in deuterium-tritium fusion targets." The NIF researchers expect to achieve a self-sustaining fusion burn reaction with energy gain within the next two years.

Subscribe now to Laser Focus World magazine; it’s free!

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.