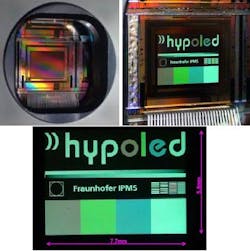

HYPOLED digital VGA full-color OLED projection microdisplay achieves 'first light'

Fraunhofer IPMS (Dresden, Germany) has achieved "first light" with its digital VGA full-color organic LED (OLED) microdisplay—a milestone for the European "HYPOLED" project.

The device has VGA resolution (640 x 480 x 3 colors), an active area of 7.7 x 5.8 mm², a chip size of 12 x 11 mm², monochrome and full-color versions, digital pixel cells, 24 bit parallel digital video interface, I²C configuration interface (including color, contrast, and gamma correction), 50 or 60 Hz frame rate, temperature monitoring, and test modes (test patterns). The chip is fabricated on a 0.18 micron CMOS 200 mm backplane wafer and operates with a core supply of 1.8 V. All digital inputs and outputs are 1.8 V interfaces. An effective OLED voltage of up to 6.7 V can be applied (depending on specific OLED stack) with a voltage of -5.0 V at the common OLED cathode.

To see samples, go to SID Spring Meeting

Researchers at Fraunhofer IPMS are fully characterizing the device, as well as incorporating it into head-mounted displays and microprojectors (in collaboration with HYPOLED partners). Samples and further HYPOLED achievements will be shown during the Society for Information Display (SID) Mid Europe Spring Meeting 2010 "Personal Projection and Information Displays: OLED, MEMS and emerging technologies for head-mounted displays, head-up displays, flexible displays and picoprojectors," to be held in Dresden, Germany on March 18 and 19, 2010 (http://www.ipms.fraunhofer.de/sidme2010).

HYPOLED is a collaboration between European partners funded under the STREP ("Small and medium-scale focused research project") scheme of the European Commission's (EC) Frame Programme 7. The project is targeted towards "High-Performance OLED-Microdisplays for Mobile Multimedia HMD and Projection Applications." It got underway in January 2008 and is scheduled for completion in June 2010. Fraunhofer IPMS is coordinator of this project; further partners are Mobintech A/S (Denmark), microoled SARL (France), Fraunhofer IOF (Germany), Universität zu Köln (Germany), University of Edinburgh (UK).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.