Sampling probes enhance remote chemical analyses

Multiple fibers optimize off-line fiberoptic sensor performance for absorption, reflectance, and Raman spectroscopy.

S. E. Nave, P. E. O`Rourke, and W. R. Toole

Recent improvements in fiberoptic sampling probes, coupled with the development of multichannel array-type spectrometers, have led to increased interest in the use of remote spectroscopy for on-line monitoring and process control. The corrosive and radioactive nature of many chemical-processing environments makes fiberoptic techniques essential for on-line monitoring at nuclear-material production facilities such as the Savannah River Site (SRS, Aiken, SC). Fiberoptic spectroscopy can result in rapid, more economical site mapping, making it useful at environmental remediation sites. Because the act of taking a sample can often alter its state, remote analysis techniques also improve data quality. Fiberoptic sampling probes can be used with absorption, diffuse reflectance, and Raman spectroscopy.

Absorption spectroscopy

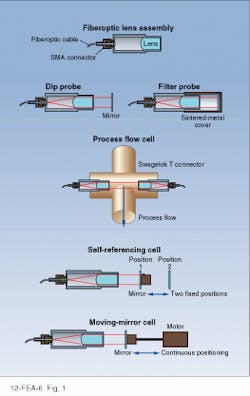

Since the 1970s, researchers at SRS have been developing fiberoptic ultraviolet (UV)/visible absorption-spectroscopy systems for on-line monitoring. This approach can be successful for clear or filtered fluids, and several different probe configurations have been developed to solve particular monitoring problems at SRS (see Fig. 1). As a result of the SRS technology-transfer program, these probe designs have been licensed to several companies and are commercially available.

In one application, a UV absorption instrument monitors ammonia-removal efficiency of a scrubber in the exhaust system of a glass melter during the vitrification of radioactive waste. This instrument includes a miniature spectrometer, a deuterium-lamp UV source, and a multiplexer that allows the same spectrometer to monitor multiple process cells. The 0.5-m-path-length sample cells that interface with the radioactive exhaust from the vitrification process are isolated in a containment hood. Fiberoptic sensors allow the other system components to be kept in an area free from radioactive contamination and radiation exposure.

This type of instrument can be used for monitoring gaseous emissions in an off-gas stack. By directing a collimated beam of light across the stack via lenses coupled to the remote system with fiberoptic cable, toxic gases such as ammonia, benzene, chlorine dioxide, sulfur dioxide, and nitrogen oxides could be monitored at parts-per-million levels.

Ultraviolet absorption has several advantages over Fourier-transform infrared measurements for monitoring process exhaust. Because UV measurements are not affected by water in the off-gas stream, complicated water-removal systems are not required, reducing system costs. Removal of particulates to reduce background optical scatter is the only required sample preprocessing; this can be addressed by an in situ filter system.

Diffuse reflectance

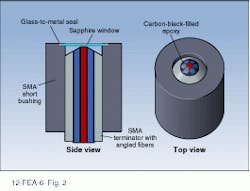

Absorption spectroscopy requires translucent or transparent sample media. Filtration can be used as a sample-preparation method, but it is not always a feasible solution for continuous monitoring applications. To permit in situ analysis of solids or slurries, the Savannah River Technology Center of the SRS has developed a simple, rugged, silica-based fiberoptic

diffuse-reflectance probe. More-sophisticated Raman and near-IR (NIR) diffuse-reflectance probes have been developed based on this design (see Fig. 2).

For diffuse-reflection measurements, white light is transmitted through the six outer fibers, and scattered light is returned by the central fiber. When the probe is used for Raman measurements, laser light is sent to the sample via the central fiber, and the scattered return light is collected by the surrounding six fibers.

Because the faces of the six outer fibers are angled, their cones of acceptance/emission are refractively bent inward and, therefore, cross the light cone of the central fiber at a common point near the probe tip. This design concentrates sample volume near the tip, typically enhancing signals in opaque slurries or solids by factors of five to ten compared to flat-tip fiberoptic probes.

This is a rugged probe with no optical alignment problems. When it is used in liquids, however, a window must be placed over the probe tip so that the index of refraction of the medium adjacent to the fiber will be constant and smaller than that of the silica fiber. A thin sapphire window inserted just beyond the probe tip in the region before the source/collection light cone intersection minimizes crosstalk between source and pickup fibers. The window is gold-brazed into a metallic or ceramic tube that provides a hermetically sealed cover to protect the probe tip from the process stream.

Raman spectroscopy

NIR absorption spectroscopy is very useful for on-line analysis in simple systems. Unlike peaks in the fingerprint mid-infrared region, however, NIR absorbance bands are quite broad. The lack of well-defined peaks makes NIR absorbance difficult to use for complicated mixtures, even with chemometric data processing. Fiberoptic spectroscopy can be extended to mid-infrared wavelengths where molecular vibrational peaks are narrow and well resolved, but the fiber required for this wavelength region is more expensive and fragile, with higher optical attenuation. In addition, water severely interferes with many analytes of interest, preventing application of mid-IR spectroscopy in most aqueous systems.

Raman scattering makes it possible to obtain spectral information similar to mid-infrared absorbance spectra, but the process is shifted into the visible wavelength region for easier transmission with normal silica fiberoptic cables. In the Raman process, a single frequency of light is scattered by the molecules in a sample. Most of the scattered light has the same frequency as the incident light (Rayleigh scattering), but occasionally it is frequency-shifted by an amount equal to one of the resonant frequencies of the molecule. These frequencies arise from molecular rotational, vibrational, or electronic states. Raman spectroscopy generally measures frequency shifts from vibrational modes of molecules.

As in mid-IR absorbance spectroscopy, the pattern of frequency shifts is an excellent indicator, or fingerprint, of the types of molecules present, and the optical intensity at the shifted frequency is proportional to compound concentration. The Raman process has a small scattering cross section, thus making high-intensity laser sources and high-sensitivity charge-coupled-device (CCD) detectors necessary elements of Raman spectrometers.

When doing Raman measurements with fiberoptics, one must minimize the nonshifted sample-induced scattered and reflected light returning to the spectrometer, as well as reduce fluorescence and silica Raman scattering generated in the fiber itself. To filter out this noise, light from the excitation fiber passes through a narrow bandpass filter at the fiber tip that transmits the laser frequency but rejects signals arising from the fiber (silica Raman and fluorescence) and extraneous light from the laser source (plasma lines, fluorescence, or superluminance). Light returning through the collection fibers passes through a long-pass optical filter that rejects scattered and reflected laser light but transmits Raman and fluorescence signals from the sample.

SRS Raman probe design

There are several commercially available fiberoptic Raman probes. Those available from Dilor Instruments SA (Edison, NJ) and EIC Laboratories (Norwood, MA), for example, feature efficient dual-fiber designs incorporating micro-optics, beamsplitters, and filters at the probe tip. These probes use single-strand optical fibers for excitation and collection, which, with cable costs running approximately $20/m, significantly reduce cost for long fiber runs. Because they require stringent precision machining and optical alignment, however, costs range from $5000 to $8000 per probe. System optics allow a variable analytical spot size and sample-to-probe distance, but optical efficiency is compromised if sample distance cannot be maintained.

To make a more rugged fiberoptic probe for Raman measurements on solids or slurries, we have designed a probe that eliminates as many optical elements and surfaces as possible (see photo on p. 83). The diffuse reflectance probe tip is modified for Raman scattering measurements by inserting thin dielectric filters into the fiber path 3 in. from the probe tip (see Fig. 3). These filters are sandwiched between fibers held in standard SMA connectors. Probe tips and filters easily can be replaced to accommodate a change in laser excitation frequency, or in the event of damage.

The probe is economical (about $800 per probe) and easily fabricated without precision optical elements or complex alignment procedures. Furthermore, the sample-to-probe geometry is easily reproducible, because the probe window is placed in contact with the sample rather than held at a fixed standoff distance. The most efficient probe design, however, uses six collection fibers. Given that this fiber costs roughly $60/m, this design can be expensive if long fiber runs are required.

The choice of optical filters has an effect on the data obtained. Consider the Raman spectrum from a powder of sodium nitrate, generated by a diode laser delivering 20 mW of 780-nm ouput to the probe tip (see Fig. 4). A laser pass filter installed in the excitation fiber removes super-radiance and fluorescence background from the laser and significantly reduces the silica-fiber Raman scattering. When the laser rejection filter is put into the collection fibers, the remaining silica Raman scattering is reduced to a very low level. The Raman spectrum of a Tylenol tablet illustrates the fingerprint region and total spectral coverage of the system (see Fig. 5).

Rugged, portable, powerful, and stable coherent sources are required for Raman process measurements. Tunable external-cavity diode lasers or diode-pumped solid-state lasers not only meet these requirements but run on 110-V power with no external cooling required. Currently, 500-mW external-cavity diode lasers operating at 780 nm are available, as well as diode-pumped, frequency-doubled Nd:YAG lasers that produce 400 mW at 532 nm.

The 780-nm laser wavelength can significantly reduce sample fluorescence, which is a problem for most organic samples. However, CCD detector sensitivity falls off rapidly past

1000 nm, limiting the spectral range of the Raman spectrum to about

2500 cm?1. If the excitation wavelength is lowered by using a 680-nm laser, the spectral range defined by the 1000-nm limit of the CCD will be 4000 cm?1 and will include the important C-H and

O-H stretching bands. The O-H bands are particularly important for aqueous slurries because they allow analyte Raman intensities to be ratioed to the water Raman intensity to remove effects of variable probe coupling efficiencies and laser power drift. External-cavity diode lasers at this wavelength are being developed and should be available in the near future.

At SRS, fiberoptic Raman probes are being developed for the in situ chemical mapping of radioactive waste-storage tanks to answer questions about homogeneity and stratification. Waste-tank contents are caustic slurries of metal hydroxides and crystallized nitrate salts at temperatures up to 90!C and radiation fields up to 10,000 rad/h. Radiation severely darkens silica fiberoptics at UV and visible wavelengths, but our testing has shown that this phenomenon has a negligible effect for wavelengths longer than 700 nm.

Probe designs for interfacing to corrosive chemical processes are being evaluated jointly between SRS and commercial chemical-manufacturing companies. Other uses of Raman spectroscopy at SRS are identifying organic pollutants in soil by deploying the probe in a cone penitrometer and measuring hydrogen, nitrogen, and oxygen gas mixtures in the off-gas from certain SRS processes.

For decades, Raman spectroscopy has been confined to research laboratories because instruments were large, complex, and expensive, and the results required expert interpretation. Recent technological advances in fiberoptics, diode lasers, CCD detectors, dielectric and holographic optical filters, grating spectrometers, and chemometric data analysis have greatly simplified the practice of Raman spectroscopy, and it is ready to move from the research laboratory to the real world for remote chemical analysis.

Exploded view (top) of fiberoptic Raman

probe (bottom) shows in-line dielectric

filters that eliminate Raman scattering

due to the silica fiber.

STEVEN P. ASHE/SRS

FIGURE 1. Fiberoptic probe can be configured for a variety of process interface possibilities, depending on sampling requirements.

FIGURE 2. The outer six fibers of the seven-fiber scattered-light probe tip for diffuse-reflectance measurement transmit the outgoing white light signal, while the central fiber channels the return.