Fresnel optic makes Young's interferometer achromatic

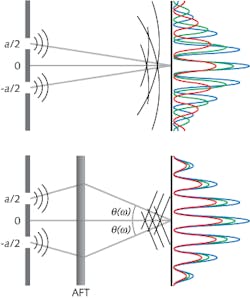

Measuring partial coherence of light is sometimes done using the classic Young’s two-pinhole interferometer, with the fringes’ reduction in modulation depth away from the axis being the quantitative measure of the level of coherence. But the Young’s interferometer suffers from the problem that most interferometers have—a lack of depth away from the axis being the quantitative measure of the level of coherence. But the Young’s interferometer suffers from the problem that most interferometers have—a lack of achromaticity due to the fact that fringe spacing scales with wavelength. While this isn’t a problem when looking at a single narrow band of wavelengths, a larger number of bands end up creating a low-visibility smear.

To solve this problem, researchers at the University of Eastern Finland (Joensuu, Finland), Aalto University (Aalto, Finland), and the Royal Institute of Technology (Kista, Sweden) have created an achromatic Young’s interferometer by inserting an achromatic Fresnel transformer (AFT) in the interferometer’s path. The AFT is essentially a diffractive (Fresnel) optic with a transverse scale factor that cancels out the spectral dependence of the interferometer’s fringe spacing. In an experiment using lasers with 473, 532, and 633 nm wavelengths, the three sets of fringes meshed completely, allowing the researchers to find the coherence of each of the lasers. Contact Kimmo Saastamoinen at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.