Sponsored Content

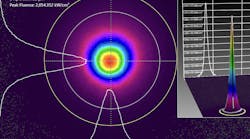

Overcoming the Challenges of Measuring High Power NIR Lasers

Related To: Ophir, an MKS Instruments Brand

Sponsored Recommendations

Sponsored Recommendations

Laser Assisted Wafer Slicing with 3DOF Motion Stages

Dec. 18, 2024

Free Space Optical Communication

Dec. 18, 2024