The global market for industrial lasers and laser systems

During LPMS, Arnold Mayer of Optech Consulting presented his analysis of the global market for industrial lasers and laser systems—and, remarkably, the market for laser systems for material processing hit a new record volume: $21 billion in 2021.

“If we look at the market segments, high-power laser cutting and welding systems hold by far the largest share of nearly half of the market,” says Mayer. “Systems for microelectronics processing account for about 1/4 of of the total. Marking systems make up 10% share of the market, while other systems like lasers with less than 1 kW average power account for a share of 18%.”

The applications are divided into two major segments: macroprocessing systems, which makes up about 75% of the market, and microelectronics processing (microprocessing) systems, which comprises about 25% of the market.

Laser macroprocessing systems include: laser systems for cutting, drilling, welding metals and plastics, marking, additive manufacturing, ablation for cleaning, and surface treatment. This group includes high-power processing (1 kW+ average power), low-power processing, and low-power precision processing (except microelectronics processing).

Laser microprocessing systems include: laser systems used in microelectronic manufacturing for ablation and structuring, lithography, annealing, cutting, drilling, and joining processes for specific microelectronics manufacturing. Microelectronics manufacturing includes semiconductors, LEDs, flat panel displays, PCBs, electronic components and hybrid circuits, solar cells, battery (excluding battery packs), fiber-optic components, MEMS, and microfluidic devices.

“The 2020 global market for laser systems and materials processing is broken into four segments that make up $17 billion: electrical and electronics industry (39%), metal processing and job shop sector (35%), nonmetal processing sectors (9%), and the automotive industry (17%),” Mayer explains.

While he hasn’t done the analysis yet for 2021, he doesn’t expect that the share shifted more than one or two percentage points last year.

One important takeaway, he points out, is “capital expenditures in the areas of electronics, automotive, and general metal and sheet metal processing are essential for the demand for laser systems and its ups and downs.”

Geographic market breakout

The geographic breakout for the global market for laser materials processing systems for 2021 looks like this: Europe 19%, America 16%, China 35%, and Asia and others make up the remaining 30%.

“Today, China alone consumes 35% of all industrial laser systems by value,” Mayer says. “For high-power cutting and welding systems, China’s share is within the range of 40% for 2021. This isn’t surprising, given the country’s share in global manufacturing and laser relevant industries. A major driver in recent years was the availability of low-cost systems, especially for marking and cutting, which led to surging unit sales in China. During the past decade, the manufacturing industry in China rapidly adopted laser processes. Today, the diffusion of laser processing into manufacturing has reached a level comparable to that in the U.S. or Europe.”

Mayer frequently fields questions about the role of China as a consumer of industrial lasers and systems, and is increasingly hearing questions about the role of China as suppliers as well.

“China’s 5-year moving average indicates a long-term slowdown of growth in global manufacturing,” he says. “China’s laser systems market’s 5-year moving average also shows a decrease in the growth rate. 2021 was an excellent year for China’s exports, which is a major driver of laser-based manufacturing. It should be noted that the strong growth in the first half of the year is partly due to the base effect of a depressed market the year before. The growth rate in the second half of the year decreased.”

Industrial laser market

Laser oscillators for materials processing accounted for a global market of $5.2 billion in 2021, which corresponds to about 25% of the volume of the laser machine market.

“While the figures for 2021 are preliminary estimates, fiber lasers account for about 52% of the total,” Mayer adds. “The majority of non-fiber lasers used today are for wavelength reasons.”

During the past 10 years, fiber lasers increased from 15% to more than 50%, while the market for other laser types nearly stagnated.

High-power fiber lasers

The power of fiber lasers used on high-powered flat sheet metal cutters is increasing steadily, Mayer says, and 10 kW and above is quite common today.

“Decreased laser and system prices are driving unit sales in cutting and more recently also in welding,” Mayer notes. “Unit sales of kilowatt-range fiber lasers has increased more than 10-fold within the past five years.”

The price/watt for high-power fiber lasers has decreased within the past five years: 70% for regular fiber lasers, and 85% for low-cost products (China).

“The market is presently split into two groups: regular products that excel in product quality, uptime, lifetime, and worldwide service vs. the cost advantage of low-cost products is substantial,” says Mayer.

Market trends and forecast

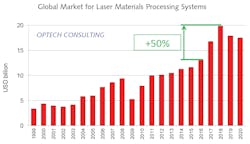

In 2017 and 2018, the market grew by an accumulated 50% within only two years (see figure directly below). “This steep market increase was due to strong demand within all major end industries,” Mayer says. “In the electronics industry, display manufacturing drove the market, particularly the applications of annealing, cutting of displays, and cutting of touch screens.”In the semiconductor segment, “packaging applications increased and EUV got market traction,” he adds. “In the PCB industry, laser cutting applications including for liquid crystal polymers added to market growth. And in the automotive industry, e-mobility laser applications drove the market.”

Global market for laser materials processing

A 10% market decrease in 2019 for laser materials processing was the result of a downturn during previous years (see figure directly below).“Consumer electronics sharply reduced investments due to decreased smartphone sales,” says Maher. “The automotive industry cut back investments due to decreased car sales, and the market in China took a dip after many years of strong growth.”

So we entered 2020, the first year of the pandemic at the 10% reduced market level. “At the beginning of 2020, before COVID-19 became a pandemic, expectations for the market development were slightly positive,” explains Mayer. “Spending in the consumer segment had already started to recover in the second half of 2019. When COVID-19 hit, financial institutions such as the International Monetary Fund and the World Bank expected the global economic output to decrease by about 5% in 2020, but things turned out to be less negative and the economic forecasts were adjusted at less negative levels.”

Although the market for industrial laser systems improved during the year, the laser systems market ended the year with a small decrease of 2%. “The market in several segments even increased year over year, such as the consumer electronics industry and by geography, in China and several other Asian countries. Demand in most other parts of the world, however, decreased in 2020,” he says.

2022 forecast for the global industrial lasers systems market

In 2022, Mayer expects double-digit growth for the industrial laser systems market.

“This expectation is based on the forecast positive macroeconomic environment,” Mayer says. “Expectations for global GDP growth during 2022 are currently around 5%. While the GDP growth is reported with inflation adjusted, we report the laser systems market in current U.S. dollars and with nominal growth rates. To keep pace with the GDP growth, the laser systems market needs to grow by about 8% in 2022. Presently, we expect that the laser systems market will outpace GDP growth and be slightly above 10%.”

For the years 2022 to 2026, “we expect growth rates in the high single-digit range, subject to a steady macroeconomic environment,” he adds.

CONTINUE READING >>>

Sally Cole Johnson | Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors. She wrote for the American Institute of Physics for more than 15 years, complexity for the Santa Fe Institute, and theoretical physics and neuroscience for the Kavli Foundation.