Photonics Products: Optical Filters - Multiband coated filters redefine performance standards for scientific applications

Multiband filters can be categorized into a variety of classes that solve unique optical problems. Each class presents its own set of fabrication challenges, placing limits on what is practically achievable and affecting the reliability of the thin-film manufacturing process. By understanding the scientific and industrial applications for multiband filters, the various filter classes and manufacturing possibilities are better understood.

Multiband filter applications

Common to all multiband filters is the ability to allow multiple but distinct wavelength regions—typically ranging from the ultraviolet (UV) to the mid-wave infrared (MWIR), or approximately 280 nm to 5 μm—to transmit through the filter while blocking the bands in between.1 Multiband filters exhibiting this comb-like spectral structure are a subset of hard-coated, dielectric thin-film optical filters made by depositing alternating layers of materials with varying indices of refraction onto a substrate.

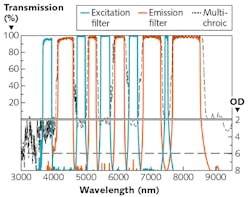

Multiband optical filters are critical to applications in the life sciences. In fluorescence microscopy, multi-bandpass excitation and emission filters are used in conjunction with multichroic beamsplitters to allow for the simultaneous detection of multiple fluorescent tags in a single sample. Ever-increasing advances in this field, such as new classes of switchable monochromatic LED and laser light sources, have increased the demand for high-performance multiband filters having extremely high transmission (93–98%), deep blocking (optical density >OD5.5 by measurement and >OD8 by design), and steep transitions between bands (near-vertical slopes approaching < 1%).

Additional advances in laser fluorescence and Raman spectroscopy applications have driven the demand for high-performance multi-notch filters that maintain broadband transmission while concurrently blocking multiple laser lines. The amount of laser light required to energize a fluorophore into an excited state is much higher than that of the returned Raman signal, which is inversely proportional to the fourth power of the excitation wavelength. In some cases, this means detecting a fluorescence marker 1012 smaller than the excitation intensity. It becomes critical to block superfluous light in the system, as to not flood the emitted signal at the detector. This is accomplished with deep attenuation (>OD6) at the laser wavelengths. If the notch edges are not steep enough, then the signals close to the laser wavelengths will be lost because of the close wavelength proximity between excitation and emission modes.

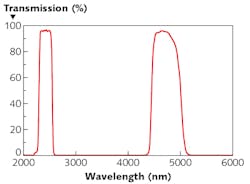

Many other disciplines are now benefiting from this surge in high-performance multiband thin films, including remote sensing, laser blocking, semiconductor fabrication, and industrial monitoring. For instance, low-passband ripple and essentially zero absorption in the water band (2.7 μm) from a dual-band IR filter can monitor climate change (see Fig. 1). Fabricating this filter requires a very stable coating process, since most traditional processes contain some trace of water during deposition or tend to absorb water post-coating because of their porous nature.

From filters with more than 10 passbands, to precision thin-film coatings designed to fit a specific spectral shape, to filters designed to control group delay dispersion across multiple passbands, new technologies are redefining the term "multiband."

Multiband performance continues to improve with respect to the number of bands, throughput, blocking levels, and spectral edge steepness. In many ways, multiband optical filters now rival classic single-band devices by delivering the same flat-top profiles and deep-OD blocking in series, enabling designers to make their optical systems more compact and efficient.

The design and fabrication of multiband filters is non-trivial even for the single band case, requiring a high-level understanding of the principles of constructive/destructive interference and a sophisticated process to monitor and control material deposition. At Alluxa, we classify multiband filters into five broad classes: 1. wideband; 2. narrowband; 3. edge dichroic; 4. notch; and 5. filters with arbitrary spectral shapes. Increasing the number of bands adds complications unique to each filter class, requiring consideration of key factors in the manufacturing process.

Multi-wideband filters

Multiband filters with relatively wide bandwidths on the order of 20 to 50 nm are prevalent in life science applications, with one such example being a bioimaging system that requires multiple illumination bands for excitation and emission.

Transmission can average 90–95% within the passband, while average blocking levels range from OD5 to OD6 between bands. Typically, in multiband filters, the transitions between the passband and blocking bands are 2–3% of the wavelength, although narrower spectral transitions are possible.

Excitation (EX) and emission (EM) channels are fabricated separate from one another by thin-film deposition methods derived from principles of interference, but specified to work together. Multiband EX and EM filters require strategic placement of transmission and blocking channels, which need to be maintained during production—that is, control and accuracy of edge positions are critical for each band and for each respective filter in the system. Edge positions define the mid-point transition from high OD blocking to high %T (cut-on) or, conversely, the transition from high transmission to deep OD (cut-off), establishing boundaries for each channel (see Fig. 2).Overlap of EX/EM bands or insufficient blocking between bands can create unfavorable crosstalk in a system, which needs to be considered and addressed during the design phase by ensuring that the collective OD level between bands is >OD6 preferably, although >OD5 is acceptable in some cases.

Tight control of cut-on/off points is achieved through precise monitoring methods, where individual layers of dielectric material are measured and adjusted in real time as they are deposited with alternating high (H) and low (L) index layers. It is possible to correct layer errors in situ with sophisticated monitoring techniques, which also helps to eliminate common manufacturing errors such as ripple, an effect of HL material mismatch where the transmission levels vs. wavelength vary undesirably.

Because hard-coated wideband filters with more than four bands are deposited on a single glass substrate, a precisely controlled and stable manufacturing process becomes crucial as the band count increases to keep the edges sharp and well defined with respect to wavelength position. Uniformity issues caused by rate drift within a run could cause adverse shifting of the bands. The resulting spectral overlap between the EX and EM channels translates into reduced contrast in the final fluorescence image.

Multi-narrowband filters

Narrowband filters transmit wavelength bands less than 10 nm wide, and several in series are referred to as multi-narrowband filters—similar in function to multi-wideband filters, but often more challenging to make.

Narrowband designs rely on stacked Fabry-Perot resonant cavities with dielectric reflectors composed of quarter-wave-thick layers, spaced apart by cavities multiple half-wavelengths across.2 Multi-cavities are used to "square up" the spectral wave shape, resulting in the transmitted light having a flat-topped spectrum when compared with a single-cavity design, which is more rounded.

Making a single-band, multi-cavity filter is a challenge for most coating deposition systems. A computer-controlled variation on the turning point method, known as spectral monitoring, is most effective to accurately control deposition thicknesses for each individual layer.3 During the coating process, the filter is constantly measured and variations in thickness are compensated for, taking into account thickness errors associated with multiple layers. This approach facilitates remarkably reproducible low-ripple narrowband filters that consistently match theory.

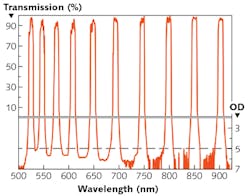

Multi-narrowband filters allow the optical designer to parse the spectrum in arbitrary ways, opening up a vast potential of applications used in conjunction with today's high-power light sources. For example, Alluxa manufactures a 10-channel filter that produces a comb of wavelengths in the visible spectrum with flat-topped, high transmission in the bands and >OD5 blocking between bands (see Fig. 3). After passing white light through the filter, each individual band is easily redirected and independently analyzed.Multi-edge or 'multichroic' filters

Multichroics, commonly referred to as beamsplitters, are particularly popular in conjunction with multi-wideband filters in EX/EM systems. Multichroics divide the input spectrum into two beams—one in reflection, the other in transmission—and are generally used at 45°, although other angles are possible. The filters are bidirectional and are used to both combine and separate the spectral bands as needed.

Multichroics are usually single-sided filters with second surface antireflection films to avoid ghost imaging. Sharp transitions from reflection to transmission (and vice-versa) enhance image contrast for many applications, including fluorescence and multispectral bioimaging. For implementation in these systems, dichroic filters must possess low angle shift, low polarization splitting, and typically excellent flatness of both reflected and transmitted wavefront to eliminate any noticeable focal shift that could adversely affect imaging quality.

In specific cases, these filters require control of phase or group delay dispersion (rather than the transmission amplitude) over distinct passbands. One specific example is a quadchroic beamsplitter that controls the phase of reflected light for all six excitation lasers integrated into a 3D structured illumination microscope (3D-SIM). A final composite image is produced after the excitation light is manipulated into multiple 3D-SIM configurations. Controlling both amplitude and phase requires careful attention during design, but also necessitates a deposition capable of producing coatings that align very closely to theory.

Similar to wideband filters, the 50% cut-on/off edge location is critical. Because design layers are often non-quarter-wave thicknesses, deposition techniques must minimize layer errors. For filters designed to work at non-normal angles of incidence, measurement process and evaluation is non-trivial, particularly for more than two transition edges in series. Substrate thickness and polarization splitting can present measurement limitations such as beam deviation and translation of the 50% edge that can affect evaluation of the spectral properties of the filter.

Multi-notch filters

Possessing the inverse spectral profile of multiband filters, multi-notch filters block or reflect (rather than transmit) discrete wavelength bands of interest. The filter shape and design structure differs somewhat, but generally, these filters aim to increase in-band rejection and maximize transmission for out-of-band light.

Introduced more than 20 years ago, multi-notch filters were primarily designed for human laser protection and machine vision applications. While still used for that purpose, performance has greatly increased with an abundance of new applications. For example, 3D cinema uses simple notch filters to divide the visible spectrum into two non-overlapping and offset spectral combs, one for each eye. Raman systems, on the other hand, require ultra-narrow notch filters to block the laser stimulus light and focus on the Raman signal. Surgeons require narrow, color-corrected notch filters to block reflection from the working laser during surgery, while maintaining the neutral color appearance image through the filter. The spectral correction features are typically comprised of partial- or full-notch shapes in the spectrum to balance the CIE white point of the filter in transmission.

Multi-notch filter design becomes more challenging as OD level increases and bandwidth narrows, since layer count and complexity increase roughly linear with OD level and inversely with bandwidth. Similar to multi-narrowband filter structure, multi-notch design demands high layer accuracy and control to flatten out-of-band transmission regions and steepen blocking profiles.

When possible, designers try to capitalize on design harmonics (a 266 nm/532 nm/1064 nm triple notch, for instance) to minimize random errors during fabrication—these harmonics provide natural blocking regions. For example, a 1064 nm notch is modified with relative ease to also block the 532 nm band, simply by reconfiguring the ratio of H and L materials within the repeating thin-film stacks. In this way, one design gives rise to two notches rather than two notches constructed independently, and then arranged to work within the same design.

Multibands with arbitrary shapes

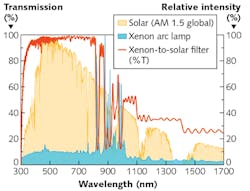

Arbitrary multibands do not fit the classic shape or structure of the previously described filter classes. Instead, these filters may use a "target" profile to manipulate incident light into multiple bands with defined transmission variation, thus creating an extremely custom-tailored response curve. For example, a solar filter can shape the output spectrum of a standard light source to match the spectrum of the sun (see Fig. 4).For obvious reasons, these designs require a large amount of computing power during the design phase. During fabrication, they often suffer from random deposition errors that can affect the target transmission magnitude and location. Typically, manufactured filters achieve spectral shape targets to levels of ±5% or better of theory, although it depends on the exact profile and features of the curve.

Multiband filters with cutting-edge levels of performance continue to push the boundaries of what is possible in optics. As demand continues to grow, thin-film filter manufacturers will continue to engineer innovative ways to fabricate these filters at competitive prices.

REFERENCES

1. See http://bit.ly/1qgrS3H.

2. See http://bit.ly/1rIeGpK.

3. H. A. Macleod and D. Richmond, Optica Acta, 21, 6, 429–443 (May 1974).

Amber Czajkowski | Product Line Manager, Alluxa

Amber Czajkowski is product line manager at Alluxa (Santa Rosa, CA); she previously served as a thin-film engineer at Edmund Optics (Barrington, NJ) from 2009 through 2014.

Rance Fortenberry, Ph.D. | Director of Technology, Alluxa

Rance Fortenberry, Ph.D., is director of technology at Alluxa (Santa Rosa, CA).

Peter Egerton | Executive Vice President of Business Development, Alluxa

Peter Egerton is executive vice president of business development at Alluxa (Santa Rosa, CA).

Mike Scobey | CEO, Alluxa

Mike Scobey is CEO at Alluxa (Santa Rosa, CA).

Alannah Johansen | Applications Specialist, Alluxa

Alannah Johansen is applications specialist at Alluxa (Santa Rosa, CA).