Deep Dive into Optics: Clear Aperture

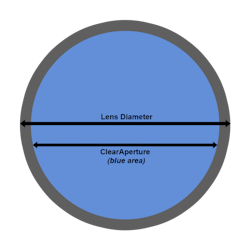

During the manufacturing process, a lower quality surface near the edge of an optical component is created. The diameter of the area inside of the optical component that must meet optical requirements (such as surface quality, surface accuracy, coating, etc.) is called the clear aperture. Due to manufacturing constraints, it is impossible to produce a clear aperture exactly equal to the entire size of the optical component.

Clear aperture can be expressed in a measurement such as millimeters or as a percent of the overall surface area of the lens. For example, a lens diameter might be 186mm and the clear aperture 180mm or 96.7%.

In general, the great the clear aperture of an optical component, the more difficult it is to produce because the required specifications must be pushed out closer to the physical edge of the optic. There are different manufacturing tolerances that determine the optical component quality.