High-power UV laser has use in CFRP machining

A strong drive to increase fuel efficiency and lower carbon emissions in transportation industries is driving the use of carbon fiber-reinforced polymer (CFRP) material in the fabrication of various aircraft and automobile parts. As the material's cost continues to decline, demand and use for it will further increase. CFRP is a lightweight, strong, and durable material with good corrosion and vibration resistance, making it a good candidate to replace many metal parts. An optimally designed CFRP part can be up to 70% lighter than steel and 30% lighter than aluminum—attributes that make CFRP attractive for use in many non-transportation-related industries such as components for wind energy production, sports equipment, oil exploration equipment, and consumer electronics products.

The attributes that make CFRP a unique and useful material also make it difficult to machine with high quality. Manufacturers using CFRP in their products are also looking to decrease fabrication costs. Conventional mechanical and abrasive waterjet cutting techniques are costly because of high tool wear and operating costs, and fiber fracture and delamination of material during machining is common and results in yield loss. The use of lasers for machining provides the advantages of a non-contact process and ease of automation in manufacturing environments. Laser machining eliminates tool wear and gradual degradation in quality associated with mechanical techniques, and reduces operating costs. Furthermore, fiber damage and delamination of material during machining can be reduced or eliminated. However, there is a key challenge for laser machining of CFRP, which is to machine it with both high throughput and with minimal heat-affected zone (HAZ) formation in the material.

Pulsed UV laser capabilities

High-power continuous-wave (CW) infrared (IR) wavelength lasers with multi-kilowatt power levels can machine CFRP at higher speeds, but leave the material with unacceptably large HAZ.1-3 On the other hand, ultrafast lasers can provide low HAZ, but usually machine materials at slow speeds.4-6 So, the challenge is to find a laser source and process that deliver a good balance of speed and quality. Pulsed nanosecond lasers have shown moderate processing speeds with reasonable quality, with the wavelength often having a significant impact on results achieved. In particular, stronger absorption at the ultraviolet (UV) wavelength results in good-quality machining. A laser such as Spectra-Physics' high-power Quasar UV laser with up to >60W UV and TimeShift pulse-shaping technology is uniquely suited to ablate, cut, and drill CFRP material without damaging the fibers, and deliver both high speed and quality.

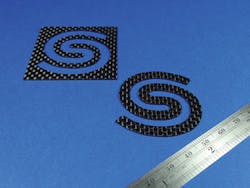

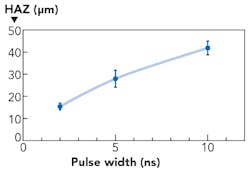

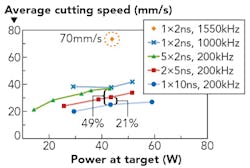

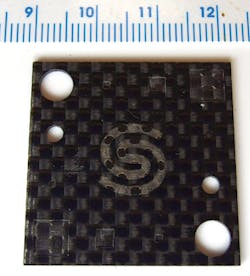

To demonstrate the capability of the Quasar UV laser, we machined 250μm-thick polyacrylonitrile (PAN)-based CFRP plate material (FIGURE 1). We varied the pulse width, power, repetition rate, and scanning speed. We also tested the burst machining capability provided by Quasar's technology. The cutting speed and HAZ—here defined as the average length of exposed fibers along the cut line—were characterized for various conditions.

Experimental results

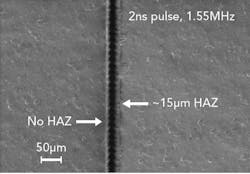

Results show that both speed and quality are achieved with this laser. The smallest HAZ of ~15μm was achieved using 2ns pulses (FIGURE 2). This is an average over a number of process conditions, and in some cases the HAZ was effectively zero. Burst machining proved to be advantageous, achieving 20–50% higher cutting speeds for the same average power (FIGURE 3). Through additional process development and optimization efforts, we have shown that this laser can cut 250μm-thick CFRP plates at 70mm/s with HAZ of < 15μm (FIGURE 4).Conclusion

We demonstrate that pulsed UV nanosecond lasers are promising for CFRP processing. With the Quasar laser, the high power and programmable pulse width/shape result in both high quality and speed for CFRP processing, including cutting, drilling, surface texturing, and cleaning. With this high-power laser, we demonstrate that low HAZ without damaging the carbon fibers can be achieved with fast processing speeds. Further work is actively being pursued to extend to other configurations of processes and thicker materials, and to expand the study of the effect of laser parameters on machining CFRP.

ACKNOWLEDGEMENTS

Quasar is a registered trademark of Spectra-Physics, and TimeShift is a trademark of Spectra-Physics.

REFERENCES

1. D. Herzog et al., "Laser cutting of CFRP using a 30 kW fiber laser," Proc. ICALEO, San Diego, CA (2014).

2. H. Hira and A. Tsuboi, "Study on cutting of CFRP plate by fiber laser," Proc. ICCM, Jeju Islan, Korea (2011).

3. F. Schneider, N. Wolf, and D. Petring, Phys. Procedia, 41, 415–420 (2013).

4. A. Wolynski, T. Herrmann, P. Mucha, H. Haloui, and J. L'huillier, Phys. Procedia, 12, 292–301 (2011).

5. R. Weber et al., "Heat accumulation in short-pulse laser processing of CFRP," Proc. ICALEO, Anaheim, CA (2012).

6. Y. C. Kim, O. Kim, S. W. Kim, and H. D. Kim, "Laser cutting of carbon fiber reinforced plastics (CFRP) by using femtosecond laser," Proc. LPM, Vilnius, Lithuania (2014).

7. F. Fischer, S. Kreling, and K. Dilger, "Surface pre-treatment of CFRP by using laser radiation, Proc. ICCM, 4792–4801 (2013).

Rajesh Patel | Independent Consultant

Rajesh Patel, now an independent consultant in laser applications, was with MKS Spectra-Physics from 2006 through 2018, with his most recent role there being Director of Strategic Marketing and Applications Engineering.

Jim Bovatsek | Applications Engineering Manager

Jim Bovatsek is an Applications Engineering Manager at Spectra-Physics (MKS Instruments; Santa Clara, CA).

Masayuki Fujita | MKS Spectra-Physics

Masayuki Fujita is with MKS Spectra-Physics (Milpitas, CA).