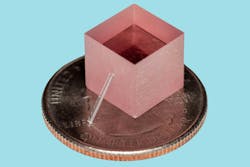

Stanford University researchers led by Jelena Vučković, a professor of electrical engineering, put a titanium-sapphire (Ti:sapphire) laser onto an integrated circuit (think square millimeters). It’s an extremely big deal because her group’s tiny alternative is four orders of magnitude smaller (10,000x) and three orders less expensive (1,000x) than any other Ti:sapphire laser ever built—and it can be fueled via a green laser pointer (see video).

Ti:sapphire lasers are currently unmatched for their performance in quantum optics, spectroscopy, and neuroscience experiments because they have the largest gain bandwidth of any laser crystal and are ultrafast. But they’re hulking beasts—think on the order of cubic feet in volume—and each costs hundreds of thousands of dollars. And operating them requires other high-powered lasers that cost on average $30,000 each to supply enough energy to function.

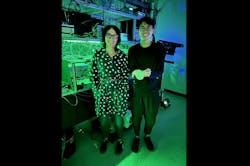

“Our group at Stanford, the Nanoscale and Quantum Photonics Lab, works on many quantum experiments involving solid-state spin qubits in materials like diamond and silicon carbide, and we rely heavily on commercial Ti:sapphire lasers,” says Joshua Yang, a Ph.D. student working with Vučković.

Beyond being expensive, Ti:sapphire lasers are complex and tend to require regular maintenance to solve issues with their operation. And Vučković’s group runs so many experiments there simply aren’t enough Ti:sapphire lasers to go around, so they end up sharing equipment and need to carefully manage their experimental timelines. There’s also a large mismatch in the power levels needed for their experiments and the output powers of commercial Ti:sapphire lasers, so they end up attenuating laser output by several orders of magnitude, which wastes most of its power.

“A chip-based Ti:sapphire laser would solve nearly every problem we’ve had with these commercial systems—and provide cheap, compact, and robust lasers with the high performance needed for precise experiments,” says Yang.

Cool laser design work

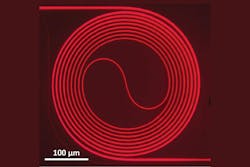

The group’s laser design work consists of two main components: a waveguide and a ring resonator.

To create it, they place a bulk layer of titanium-sapphire onto a platform of silicon dioxide (SiO2), which then goes onto a sapphire crystal. The Ti:sapphire layer is ground, etched, and polished until it’s merely a few hundred nanometers thick. And then a waveguide, which resembles a swirling vortex of tiny ridges, is patterned onto it to guide light around the chip.

And a microscale heater warms the waveguides, thereby changing their refractive index and speed of light propagating through them, which allows the researchers to tune the color (wavelength) of the light within the red to infrared wavelengths (currently 60 nm).

“Our waveguide amplifier is a spiral that increases the power of the laser light that passes through it,” Yang explains. “And the ring resonator acts both as a filter, allowing for control of the wavelength of lasing via microheater tuning, and as a recirculating element, since a laser needs a cavity—a path where the light can circulate.”

Challenges along the way

One of the biggest difficulties of dealing with Ti:sapphire lasers is that they require high pump intensities for operation. By translating the Ti:sapphire technology into high-confinement waveguides, the group accomplished two important things:

First, pump intensity is power divided by area. And by using photonic waveguides of Ti:sapphire, they were able to significantly reduce the area. “This means we need significantly less power (1,000x) to reach similar pump intensities as those used for commercial bulk Ti:sapphire systems,” says Yang. “As a result, even a cheap green diode laser is powerful enough to pump our chipscale laser.”

Second, they put a Ti:sapphire laser onto a chip. “It enables miniaturization, scaling, and robustness that free-space systems don’t have (no more moving parts), and it can use wafer-scale semiconductor manufacturing techniques for mass production,” Yang adds.

Best part of this work for Yang? It was seeing the group’s chipscale Ti:sapphire laser being used in a quantum experiment. “Seeing this tiny device replace our commercial bulky laser system in a complicated cavity quantum electrodynamics (QED) experiment was a real ‘wow’ moment—we knew we had created something very special,” he says.

One challenge Vučković’s group had to overcome to reach this point was optimization of the coupling of pump power. “For our experiments, we pumped our laser through free space,” Yang says. “But with photonic packaging techniques, it’s possible to directly integrate a green laser diode as the pump to our chipscale Ti:sapphire laser. With a packaged system and improved coupling, we could produce higher laser output powers in a robust and portable form factor.”

Since there are no moving parts involved, the chipscale Ti:sapphire lasers can be mass-produced—potentially thousands at once. In fact, the researchers are now exploring putting thousands of Ti:sapphire lasers onto a single 4-inch wafer, which will further drop the cost of the laser to next to nothing.

Applications/timeframe

Chipscale Ti:sapphire lasers will find many applications—ranging from quantum technologies like quantum computing and atomic clocks to medical applications like optical coherence tomography and two-photon microscopy.

“Hopefully this technology will be mature enough for use within these areas during the next few years,” Yang says. After graduating this summer, he will be working on a company called Brightlight Photonics to commercialize the amplifier and laser results the group demonstrated.

“Jelena Vučković and her group are now working on a tunable modelocked (pulsed) Ti:sapphire laser on a chip,” Yang adds.

Pulsed operation “will open new opportunities for the laser in quantum technologies, classical information processing, and biomedical sciences,” Vučković says.

FURTHER READING

J. Yang et al., Nature, 630, 853–859 (2024); https://doi.org/10.1038/s41586-024-07457-2.

Related Webinar

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.