MICHAEL J. TENALIO and TYLER MOORE

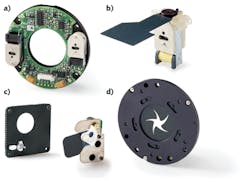

From thermography to laboratory research and laser safety, optical shutters play critical roles in system performance. To develop products such as cameras, microscopes, and laser systems, designers must match custom or off-the-shelf shutters to the requirements of the systems. In this article, we describe some of the typical applications and types of shutters best suited to meet product needs (see Fig. 1 and the table).Thermography applications

Shutters are widely used throughout the thermography world. The technology is often seen as very similar when applied to night vision and environmental assessment applications. Within each system, shutter surfaces are used to provide periodic nonuniformity correction (NUC), which results from the spatial nonuniformity in the photoresponse of detectors in the focal plane array. It is especially severe in mid- to far-IR imaging systems. In this capacity, shutters play a critical function, and each application has slightly different requirements.

As a result, when designing any variation of a thermography system, optimal performance obtained through collaborative efforts between the shutter team and the camera development team will make sure all specifications are met. Often, key requirements such as shock and vibration, operating temperature, speed, shutter life, power management, size, weight, and price point can drastically change the design.

Night vision is the most well-known example of shutter use in thermography. It is commonly seen in IR imaging systems that are used in weapon sights and security cameras. A less-known application of a shutter used in thermography is environmental assessment, which could be for first responders, industrial manufacturing, driving safety, inspection, or border security. Requirements vary for each example of environmental assessment.

Thermographic IR cameras used by emergency first responders are an interesting example of cameras being applied for environmental assessment. The emergency team needs to analyze a dangerous structural fire before entering the area. The team leader uses a commercially available thermographic camera to analyze the scene for image hotspots-this often requires a ruggedized system that can handle very aggressive use.

The same type of camera could be used in a different way by a building inspector, who will analyze the thermographic signature to evaluate a building's environmental efficiency. Heating or ventilation leaks can be identified or the wiring inspected for flaws. Portable IR cameras for these applications are typically handled with care. But even within these examples, a camera system may be designed to reach different target markets or end users.

Hybrid cameras are also available and require even more attention to detail. With the right product design, complicated optical, mechanical, and electronic challenges can be neutralized, and the result is a simpler, easy-to-use product.

Exposure control in the lab

A shutter is typically the most common and effective way to achieve exposure control within a laboratory environment. Shutters are used in many cameras from manufacturers of laboratory and microbiologics equipment. The shutter also serves to control exposure in spectroscopy or microscopy application. These imaging applications tend to have large imaging arrays that require a shutter to offer a large aperture, fast transition times, and repeatability. In other applications, the shutter controls incandescent or laser light to an apparatus. Also, shutters must be designed to suppress high-power incident radiation. Other critical requirements are very long life, fast speed for aperture size, and compact form.

In flow cytometry, for example, a system may use shutters for exposure control when analyzing a biological sample. Several vials of the sample are placed into rotary trays, and a diagnostic review cycle begins. The samples are excited by a light source, and a digital interface captures the sample data. Many things are necessary to meet the requirements for a premier flow cytometer. The design team must consider the lab throughput, processing costs, quality, consistency, and reliability (lifecycle). Each of these critical design functions is influenced or directly affected by the optical shutter.

A microscopy system also depends on a shutter for exposure control. In this application, blood may be studied for glucose, cholesterol, or other concerns. A technician reviews the slide sample under a digital microscope and compares several samples to a reference sample. To accomplish this in volume, with consistency between samples, the microscope needs to have a light source, a shutter that is synchronized to the digital camera, and a predetermined aperture and shutter speed.

As with a flow cytometry system, the design team must consider the lab throughput, processing costs, quality, consistency, and reliability (lifecycle). Additionally, light conditions, irising, and controls are often very different within this system.

Laser safety

Shutters are also a critical component in protecting the user or surrounding environment from a potentially dangerous laser illumination. Laser wavelengths can vary from near UV through the IR, and shutter blade surfaces must be designed for robust, reliable, and debris-free operation. Often these shutters must remain in functional condition for millions of cycles.

Incident laser energy can destroy blades and can cause material to be shed from the blade, which can prove catastrophic in an experiment or a manufacturing environment. Additionally, the shutters should operate in a safe mode that is defined by the designers.

Answering the right questions

Once you have identified the need for a shutter, you must understand how to achieve the best performance for the system. Shutters, though deceptively simple, have many important decision points, and it's critical to maintain high standards for quality and reliability in all key features.

Here are some of the key elements of shutter design that must be understood:

Blade coating: There are unlimited options that support life span and sensor calibration requirements. High emissivity coatings and blade materials are a specialized science requiring years of experience to master. Many coatings provide sufficient performance, but often the best option will make the difference between an average system and a superior system.

Speed: Many commercial cameras need shutters that function with microsecond precision, traveling from closed to open (or vice versa) in 10 to 25 ms or less.

Lifecycle/reliability: Varying applications require lifecycles of 100,000 up to 20 million cycles before shutters need replacement. Millions of lifecycles are necessary for the high demands of the commercial life science industry.

Power: Power is a unique concern for every design. Some systems deliver a large amount of power to the camera, such as when mounted in a vehicle. Usually, this is not the case, and power management is essential through electronic design.

Noise: This is one of the most important specifications to meet, especially in mission critical environments and with stringent MIL specs.

Environmental: When using cameras in caustic environments or in wide ranges of thermal heat/cold, robust requirements can be very difficult to achieve consistently. Although the external elements in laboratories are not challenging, they have their own requirements for safety.

Physical size requirements: Here the system size trades off with the aperture size; e.g, more blades can reduce the size of the shutter as a whole but the system increases in complexity. As a result, the shutter dimensions and aperture size relative to the optical path and the mechanical footprint must be considered.

Catalog vs. custom design: An extensive catalog portfolio can save time and effort. If a catalog does not meet system requirements, then the product development team should include experts in optical and shutter designs. The experts should function as an extension of the OEM design team.

Michael J. Tenalio is director of product management and Tyler Moore is regional sales manager at Melles Griot, 55 Science Parkway, Rochester NY 14620; email: [email protected]; marketplace.idexcorp.com.