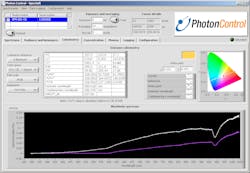

Spectroscopy software from Photon Control calculates and logs peak profile parameters

SpecSoft Pro software communicates with spectrometers through a USB 2.0 high-speed connection. It measures and color-logs CIELAB Color, L*a*b, and RBG color xyY in real time, and calculates atomic plasma scores, radiometric, and luminance values as well as concentration. The software also calculates and logs peak profile parameters such as full-width at half-maximum (FWHM), Gaussian center, and amplitude.

Photon Control

Burnaby, BC, Canada

[email protected]

More Products

-----

PRESS RELEASE

Photon Control Proudly Releases New SpecSoft Pro Software for Spectroscopy line of products

Burnaby, B.C. ~ Photon Control Inc. ("Photon Control") (TSX-V: PHO), a leading developer of precision measurement solutions, is pleased to announce the release of SpecSoft Pro Software to Photon Control's Spectroscopy product line.

Photon Control's SpecSoft Pro is feature-rich operating software; capable of communicating with all of Photon Control spectrometers through USB 2.0 Hi-speed connection providing, a real-time interface to a variety of visualization and signal processing functions.

The advantages and features of SpecSoft Pro over SpecSoft Basic include; measures and color logs CIELAB Color, L*a*b and RBG color xyY in real-time, calculates atomic plasma scores, radiometric, and luminance values; along with concentration. SpecSoft Pro has two operating modes: continuous or hardware-triggering mode. The software can calculate and log peak profile parameters including FWHM (Full width half maximum), Gaussian Center and Amplitude.

SpecSoft Basic is included with the purchase of every Photon Control Spectrometer. SpecSoft Pro and SDK C++ software are available upon request.

For more information about SpecSoft Pro and Photon Control's products please visit www.photon-control.com or email [email protected].

About Photon Control Inc.

Photon Control Inc. designs and manufactures a wide range of optical sensors & instruments to measure temperature, pressure, position, and flow. These products are used by original equipment manufacturers (OEM) as well as end-users in the Semiconductor, Oil and Gas, Power, Life Science, and Manufacturing industries. Photon Control's products provide high accuracy and reliability in extreme conditions and are supported by a team of experts that offer onsite installation, training, and support. Photon Control Inc. also provides engineering services for customized optical measurement systems. Headquartered in an ISO 9001:2008 manufacturing facility in Burnaby, BC, Photon Control Inc. is listed on the TSX Venture Exchange, trading under the symbol PHO. Additional information about the company can be found at www.photon-control.com/investorrelations.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!

LFW Staff

Published since 1965, Laser Focus World—a brand and magazine for engineers, researchers, scientists, and technical professionals—provides comprehensive global coverage of optoelectronic technologies, applications, and markets. With 80,000+ qualified print subscribers in print and over a half-million annual visitors to our online content, we are the go-to source to access decision makers and stay in-the-know.