Process diagnostics in PIAD: tracing plasma fluctuations and drifts

SINA MALOBABIC, JENS HARHAUSEN, MORITZ OBERBERG, RÜDIGER FOEST, LARS MECHOLD, PETER AWAKOWICZ, and RALF PETER BRINKMANN

High-precision optics have become a key technology in many industrial fields. As dielectric-layer optical systems become more and more complex, optical interference coatings (OICs) have been gaining increasing importance for these optics. OICs are formed by a layer stack of alternating transparent single layers of high- and low-refractive-index material. A common method for manufacturing high-end coatings is plasma-ion-assisted deposition (PIAD), which is a combination of conventional electron-beam evaporation and a plasma assist source targeted directly at the surface of the substrates. The bombardment of the adatoms (atoms adhering to the surface) by fast ions and neutrals during deposition increases their mobility and improves layer quality through an energetically advantageous position as the thin film grows.

The amount of momentum and energy applied during dielectric film growth in plasma-ion-assisted processes has a major impact on the mechanical and optical properties in the layer stack. Fluctuations and drifts in the plasma source that generates the ion beam can result in a lack of stability during the coating process and lead to poor reproducibility in film properties.

Long-term stability in coating processes, which is a major factor in guaranteeing coating functionality and increasing yield and quality, remains a challenge. Currently, process monitoring only affects the operating and deposition parameters—even state-of-the-art coating plants do not deliver any information on the plasma state. Here is presented a device called the Multipole Resonance Probe (MRP) as an economical and industry-compatible diagnostic tool to obtain deeper insight into the coating process. First results indicate that significant variations in plasma properties can occur in processes run at nominally identical operating parameters.Experimental setup

Laser Components uses PIAD to produce hafnium dioxide (HfO2) and tantalum oxide (Ta2O5)-based optical interference coatings for infrared applications. HfO2 and Ta2O5 are used as a high-refractive-index material, and silicon dioxide (SiO2) is used as a low-refractive-index material. In PIAD, the coating material is evaporated by heating using a high-energy electron beam gun in high vacuum. The coating material then expands in the form of gas particles in the direction of the substrate, where it condenses on the substrate surface and grows into a thin film. The plasma source used is an advanced plasma source (APS).1

The PIAD plant is operated using recipes for machine control to achieve the specifications of the OIC. Concerning the assist source, an important parameter is the bias voltage VB, which is strongly linked to the beam ion energy.2 However, the momentum and energy input of ion bombardment can fluctuate as plasma conditions change. Conventional coating plants do not offer measurements for analyzing and eventually controlling the plasma state precisely. Active plasma-resonance spectroscopy (APRS) is a concept in which information on a plasma is acquired by means of a high-frequency interaction of a probe. A radio frequency is fed into the plasma to take advantage of the resonance behavior of electrons, which corresponds to the plasma density. The MRP is a recent implementation of APRS that grants access to electron density;3 one of its major advantages is the operability under dielectric deposition conditions.4

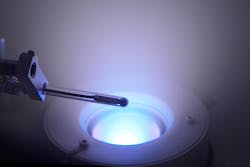

To investigate the time evolution of this type of plasma in an industrial environment, the MRP was mounted in Laser Components’ PIAD production plant (see Fig. 1). It is positioned close to the chamber wall in a midvertical location between assist-source and substrate holder. Damage of the probe by the considerable heat load present during the process is prevented by water cooling. Recording of resonance spectra, which in this case occur in a frequency range of 50 to 300 MHz, is done by a vector network analyzer (VNA). Frame rates of about 1 Hz can be achieved. For this application, it is sufficient to focus on the resonance frequency fr, which is actually a function of electron density.

Results and discussion

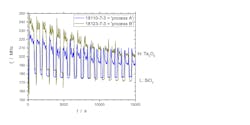

The MRP system has been operated in many production processes as a monitoring device. As a first result, it can be stated that the probe indeed works reliably under harsh conditions. So far, no malfunction of the diagnostic tool has been experienced. Presented here is data on the resonance frequency from a standard process, namely a high-reflection mirror coating consisting of SiO2/Ta2O5 layer pairs. Conventional machine control ensures constant values of VB and gas fluxes of assist-gas species argon and reactive-gas species oxygen. Specific sets of operating parameters are applied for each layer material.

Data on fr for two processes of the same kind are shown in Figure 2. High-refractive-index (H) and low-refractive-index (L) phases are clearly resolved, while each phase exhibits a variation in fr, typically a decline. Regarding the whole process time, there is obviously a decrease in fr. Fluctuations and drifts seem more pronounced for the H phases. Comparing the time traces of the two separate runs, there is a similar character but a change in magnitude: for example, for the H phases, process B shows higher fr than process A. So, concerning the monitoring data on the plasma state, the processes differ despite the fact that same production scheme has been applied. In regard to recent results published in this field,5 it is suspected that a deviation in process conditions exists that could affect reproducibility of the coating performance.

In an experimental campaign carried out under true industrial conditions for the manufacture of multilayer coatings using PIAD, the MRP was found to be a promising approach for monitoring of the plasma state. It is process-compatible and able to detect plasma fluctuations, long-term drifts, and run-to-run deviations. In conclusion, this study reveals new ways for the implementation of monitoring devices focusing on plasma properties, as well as future steps toward novel concepts for process control.

ACKNOWLEDGMENT

We gratefully acknowledge the financial support of the German Federal Ministry of Education and Research (BMBF) within the framework of the PluTO+ project under grants [LC:]13N13212, [RUB:]13N13208 and [INP:]13N13213.

REFERENCES

1. A. Zoeller et al., Proc. SPIE, 3133, 196 (1997); http://bit.ly/PIADref1.

2. J. Harhausen et al., Plasma Sources Sci. Technol., 21, 3, 035012 (2012); http://bit.ly/PIADref2.

3. M. Lapke et al., Appl. Phys. Lett., 93, 051502 (2008); http://bit.ly/PIADref3.

4. T. Styrnoll et al., Plasma Sources Sci. Technol., 22, 045008 (2013); http://bit.ly/PIADref4.

5. J. Harhausen et al., Thin Solid Films, 673, 94-103 (2019); http://bit.ly/PIADref5.

Sina Malobabic and Lars Mechold are at Laser Components GmbH (Olching, Germany; its U.S. office, Laser Components USA, Inc., is located in Bedford, NH), Jens Harhausen and Rüdiger Foest are at the Leibniz Institute for Plasma Science and Technology (Greifswald, Germany), Moritz Oberberg and Peter Awakowicz are at the Institute of Electrical Engineering and Plasma Technology at Ruhr University Bochum (Bochum, Germany), and Ralf Peter Brinkmann is at the Institute of Theoretical Electrical Engineering at Ruhr University Bochum; e-mail: malobabic@lasercomponents.com.