Mid-IR spectroscopy monitors UV-curable adhesive dynamics

Real-time measurements of spectral characteristics of many fast-curing adhesives and coatings are often limited by the measurement speed of off-the-shelf spectroscopy instruments. But by using quantum-cascade laser (QCL)-based frequency comb technology, engineers at IRsweep (Stäfa, Switzerland) can monitor the curing characteristics of adhesives and coatings on microsecond to minute time scales.

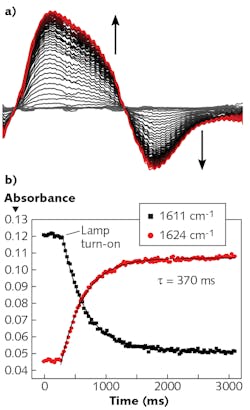

The IRis-F1 spectrometer, fitted with a diamond attenuated-total-reflection (ATR) accessory, was used, for example, to monitor an ultraviolet (UV)-triggered adhesive with a known uncured 1613 cm-1 infrared band that transitions into a 1638 cm-1 band after curing. After acquiring an initial background measurement upon cleaning the ATR crystal, the UV adhesive was applied to the sample plate and IRis-F1 measurements were taken in 25 ms increments before, during, and after curing with the UV source. Using a QCL with a 1585–1645 cm-1 source set to 4 cm-1 resolution and 1 ms acquisition time with 40 Hz repetition rate, raw spectra clearly show decay in the 1610 cm-1 band as the 1640 cm-1 band grows. A Fourier transform removes the interference fringes from the ATR and simple difference spectra are obtained by subtracting the uncured baseline spectrum. By fitting the growth and decay of spectra when the lamp is turned on, the kinetic properties of the curing process can be determined. Reference: https://irsweep.com/2019/04/24/monitoring-rapid-curing-reactions-with-the-iris-f1.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.