Mid-IR Spectroscopy: Multipass cell for optical trace-gas sensing is monolithic, compact

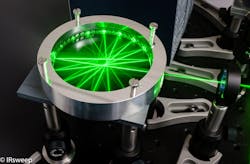

For adequate measurement sensitivity, closed-path optical instruments that sense trace gases need long optical path lengths. While this requirement is easily satisfied for large instruments, it is a problem for smaller instruments, as conventional multipass gas cells are rather bulky. To fill this need, IRsweep (Zürich, Switzerland) has introduced a small multipass cell, called the IRcell, that consists only of a small, circular mirror that folds the sensing laser beam into a dense star pattern with an optical path length of up to 4 m in a volume of only 30 ml (see figure), resulting in short gas-exchange times.

IRsweep's main line of business is mid-infrared (mid-IR) optical sensing—the company produces spectroscopic instruments that use two quantum-cascade-laser (QCL)-produced frequency combs to achieve high temporal and spectral resolution over a broad spectral bandwidth without the need for mechanical elements. Furthering this simple approach is the IRcell, which is monolithic and thus not prone to component misalignment via vibration or temperature changes. Long-path transmission measurements with an optical noise of 0.25% root-mean-squared (RMS) can be achieved.

"The IRcell consists of a single-piece, diamond-turned, gold-coated, 80-mm-diameter copper cylinder," says Markus Geiser, IRsweep's cofounder. "In the plane of the light beam, a toroidal mirror is carved into the cylinder surface. Due to the concentric arrangement of the toroidal surface, the light beam is refocused after each reflection. This leads to minimal aberration and reproducible propagation of the laser beam."

Changeable path length

The optical path length can be changed by changing the incidence angle of the optical beam, producing a star-shaped beam with more or fewer points depending on the path length. Thus, the same cell can accommodate a shorter or longer optical path. The 100-mm-diameter cell can accept a beam diameter up to 4 mm, which is focused to a point 50 mm from the cell's entrance window.1 The wavelength range of the device is vast, extending from IR to the terahertz region (with window materials changed to match the chosen wavelength).

With this cell, which has a pressure range of 0-1 bar, IRsweep is targeting mid-optical-path-length applications. "There is a range of manufacturers for multipass gas cells," says Geiser. "Most cells target the market of greater than 30 m optical path. Those cells occupy a large footprint and contain a large gas volume as compared to the IRcell. We aim at different applications, where intermediate sensitivity is required with an optical path length of 1–4 m. In such applications, we can provide significantly lower sample volumes as well as smaller dimension cells than currently available."

The IRcell provides a large spectral bandwidth of 100–200 cm-1 per pair of lasers, centered between 1200 and 2000 cm-1, says Geiser. He adds that there will be some limited freedom of choice where the user requests the center wavelength and IRsweep is working to fill the gaps to cover the whole range of 1000–2000 cm-1. Resolution will be better than 10 MHz.

Geiser also notes that IRsweep has recently introduced a new gas-cell design for mid-IR laser spectroscopy. "To further increase the optical path length, we have evaluated new optical configurations for such single-piece circular gas cells," he explains. "The considerations included different mirror shapes such as spherical and parabolic, the comparison of concentric and confocal arrangements, and the effect of various star patterns on the stability of the optical alignment. As a result, we have developed a multipass cell where a parabolic shape in a confocal mirror arrangement is carved into the cylinder wall. The parabolic mirror allows for new optical configurations—for example, an off-axis beam pattern."

REFERENCE

1. See http://bit.ly/1NsAc67 for spec sheet.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.