SPECTROMETERS: Grating-based spectrometer resolution improves without adding more grooves

Because the groove or line spacing of the diffraction grating used in a grating-based spectrometer is limited to half the incident wavelength of light, numerous hybrid techniques have been developed to increase spectrometer resolution, such as integration of the diffraction grating with Fabry-Perot interferometers or grating spectrographs, and even a combined grating/Fresnel lens. Rather than implement these hybrid designs using devices that require mechanical scanning, have spectrally varying responses, or require post-processing of the data, researchers at the Korea Research Institute of Standards and Science (KRISS; Daejeon, South Korea) have developed a purely optical approach using plane-parallel mirrors and have demonstrated a factor-of-four improvement in grating-based spectrometer resolution using two mirror pairs.1

Exploiting translational symmetry

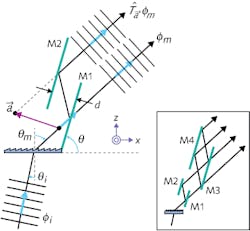

Diffraction gratings are symmetrical under translational spatial movements. If a plane-parallel mirror pair is placed onto or just above the grating to translate the fields diffracted from the grating through double reflections, the mirror pair effectively creates another virtual grating beside the original one and doubles the number of grooves (see figure). Adding an additional pair doubles the number of grooves again, increasing spectrometer resolution until practical implementation limits are reached.

In the experiment, a plane wave incident on a diffraction grating is diffracted onto a plane mirror M1 that reflects 50% of the light onto a second plane mirror M2, effectively translating the input light. By solving the grating equations to find a condition under which the original diffracted field and the translated field have the same phase, the optimal mirror angle to the grating surface and physical separation can be computed. At normal incidence, for example, the mirror separation is half the grating size and the mirror plane is 90° to the grating surface. As the incident beam becomes oblique, the mirror angle deviates from 90°.

To demonstrate spectral resolution improvement using the plane-mirror setup, a 7 × 5 mm rectangular aperture was placed on an 830 grooves/mm diffraction grating. A tunable diode laser with a linewidth less than 300 kHz delivered through a singlemode fiber (numerical aperture 0.12) was used to create the incident plane wave. A 50% reflective broadband dielectric coating was applied across half of a 1-mm-thick glass plate to create mirror M1. A fully silver-coated (100% reflectivity) glass plate constituted mirror M2, which was placed 3.5 mm from M1. After careful alignment to ensure that the mirrors were parallel, the incident laser wavelength was varied and the output was recorded as a series of diffraction-limited spots at the plane of a CCD sensor, the full-width half-maximum of the spots corresponding to the spectral linewidth Δλ.

For the first pair of nominally aligned plane mirrors M1 and M2, Δλ was experimentally reduced by a factor of two compared to the diffraction-grating only case. In this demonstration, the incidence angle of the plane wave was 5.5°. Since the optimal mirror angle was calculated as 86° for this incidence angle, the mirrors were declined by 4° from the grating surface normal. The researchers also demonstrated a resolution improvement of a factor of four using two mirror pairs.

“Grating-based, high-resolution spectrometers used for such applications as Raman and fluorescence spectroscopy are inevitably quite bulky due to the large internal gratings,” says Eun Seong Lee, a principal research scientist at KRISS. “This technique helps make these systems more compact without sacrificing resolution. Even with only one mirror pair, the spectrometer size can be reduced significantly in width and thickness. In order to improve the setup and ensure mirror pair alignment, our group is working to integrate the mirrors and grating into one device.”

REFERENCE

1. E.S. Lee, Opt. Lett., 36, 24, 4803 (Dec. 15, 2011).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.