Cavity-Enhanced Absorption Spectroscopy: Mid-IR QCL with shock tube measures CO concentrations

Researchers at Stanford University (Palo Alto, CA) have given a boost to the venerable shock-tube approach to studying high-temperature chemical reactions by using a mid-infrared quantum-cascade laser (QCL) incorporated into a cavity-enhanced absorption spectroscopy (CEAS) instrument for detection of carbon monoxide (CO).1 The in situ measurements of CO in the shock tube were made to a time resolution of 10 μs.

A shock tube contains a low-pressure chamber filled with a gas precursor mixture to be analyzed, separated by a diaphragm from a second, high-pressure chamber. With enough pressure, the diaphragm burst, forming a shock wave that travels rapidly through the precursor, compressing and accelerating it; the shock wave then bounces off the end of the chamber, stopping, compressing, and heating the precursor again.

The measured shock velocity is used to precisely determine the temperature and pressure of the shocked gas during its short shocked state of between 0.5 to 100 ms (after which the pressure and temperature decrease). During that short time span, the state of at least one component of the combusting or otherwise reacting gaseous mix must be measured many times to gather adequate info for analysis.

Low-finesse cavity

To make the time response more rapid, the Stanford group chose a CEAS setup with a low-finesse (mirror reflectivity of ~0.989) cavity, as high-finesse cavities retain light for a long enough time to lower the time resolution. The researchers explain that a 150-mm-long cavity with mirrors having a reflectivity of 0.99999 would have a time resolution of about 100 μs, which would obscure the down-to-10-μs transients that they wanted to capture.

The 150 mm cavity was formed by two 25-mm-diameter calcium fluoride (CaF2) dielectric-coated mirrors with a 1 mm curvature, both fabricated at Rocky Mountain Instrument (Lafayette, CO). The resulting cavity transmission was about 1%.

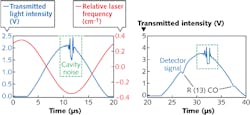

The light source was a distributed-feedback (DFB) QCL emitting 30 mW at 4.56 μm with a 0.001 cm-1 bandwidth, made by Alpes Lasers (Neuchâtel, Switzerland); the laser wavelength was scanned over a ±0.32 cm-1 spectral range by varying the injection current at a 50 KHz rate to suppress cavity coupling noise. In an interesting approach, the lowest-injection-current part of the scan was below the laser threshold, which allowed the researchers to detect the thermal emission of the gas during every scan.

Laser light transmitted through the cavity was focused onto a 2-mm-diameter thermoelectrically cooled photovoltaic mercury cadmium telluride (HgCdTe) imager made by Vigo System (Ożarów Mazowiecki, Poland), which produced an output linear in light intensity and was sampled at a 10 MHz rate. The researchers note that the combination of the low-finesse cavity, the relatively broad bandwidth laser, and the fast wavelength scanning combine to reduce cavity mode noise.

0.1 ppm detection sensitivity

The tested gas mixture contained 10 ppm of acetone in argon (see figure); the idea was to study the time-resolved appearance of CO, with one CO molecule appearing for every dissociating acetone molecule and complete dissociation of the acetone expected at 1380 K. The mole fraction of the resulting CO measurements ranged from 2 to 100 ppm, while the temperatures were between 1000 and 2100 K and the pressures between 1.2 and 1.6 atm. At a temperature of 1500 K, the detection sensitivity was measured to be 0.1 ppm.

The new approach allows studies at low reactant concentrations, say the researchers, which minimizes the undesired influence of secondary reactions that happen at higher concentrations and that can obscure the reaction effects that are intended to be measured. The group plans to further improve the detection limit by using higher-reflectivity mirrors.

REFERENCE

1. K. Sun et al., Opt. Exp., 6 October 2014; doi:10.1364/OE.22.024559.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.