Frequency Combs: On-chip, dual-comb spectroscopy source uses single-laser-pumped microring resonators

On-chip integration of dual frequency combs is not a new phenomenon. In fact, a dual-comb source based on wedge resonators using two separate semiconductor chips pumped by two independent lasers was created, but had limited optical bandwidth. And even though soliton dual combs with low beat-note spacings were reported, spectroscopy measurements were hindered by the short lifetimes of the combs because of thermal effects.1

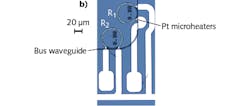

To generate dual frequency combs, a laser pumps a silicon nitride waveguide coupled to two silicon nitride ring resonators (a); parametric oscillation and cascaded four-wave mixing (FWM) in rings R1 and R2 generates frequency combs with a spectrum that is detected at the output of the chip using a fast photodiode. An optical microscopy image (b) shows the silicon nitride rings with integrated platinum microheaters. (Courtesy of Columbia University)

Now, researchers at Cornell University (Ithaca, NY) and Columbia University (New York, NY) have generated on-chip dual Kerr frequency combs with just a single pump laser and dispersion-engineered silicon nitride (Si3N4) microrings to produce a wide optical bandwidth with long coherence times. Soliton mode-locking of both combs is achieved through integrated thermal tuning, enabling narrow beat notes with linewidths of <10 kHz and optical spectra spanning 51 THz.2Pumped microring resonators

Cascaded Si3N4 microring resonators with nominal radii R1 and R2 of 50.04 and 49.98 μm, respectively, are pumped with a single laser and coupled to the same bus waveguide. These resonators have low linear loss (0.8 dB/m), high refractive index (n = 2), ultralow nonlinear absorption in the near-infrared region, and are compatible with complementary metal-oxide semiconductor (CMOS) fabrication processes. In addition, the Si3N4 waveguides have a high nonlinear index of 2 × 10-19 m2/W and easily tailored group velocity dispersion (GVD) through waveguide-geometry engineering.

To create a frequency comb, waveguides with a height of 730 nm and width of 1500 nm allow low GVD at the 1561 nm pump wavelength, facilitating broadband frequency-comb generation. Integrated platinum microheaters use the thermo-optic effect to tune the ring resonance wavelength by more than a full free spectral range (FSR) to compensate for ring radius fabrication variations (see figure). These microheaters deliver localized and targeted heat, allowing the resonance frequencies of the rings to be tuned at speeds of around 50 MHz/μs—a quicker and far more efficient process than using Peltier elements to tune chip temperature.

The microring resonators generate frequency-comb spectra spanning 51 THz (400 nm) around the 1561.4 nm pump wavelength. The frequency difference between the combs is 1.4 ± 0.8 GHz—easily measured by commercially available fast photodiodes. Essentially, dual-comb technology frequency down-converts the repetition rate of the microresonator combs for easy beat-note analysis.

A fast Fourier transform (FFT) of the signal in the time domain shows that 27 beat notes are spaced by 1.12 GHz—the mode-spacing difference of the two combs. Experimental analysis of dichloromethane near the pump wavelength of 1561 nm using this dual-comb spectroscopy source agrees well with the spectrum obtained through an optical spectrum analyzer (OSA) and a broadband supercontinuum light source, but the dual-comb technique requires several orders of magnitude less time to acquire this spectrum.

“Since both the combs are generated on a single millimeter-sized chip and pumped by a single laser, they are stable for hours without any complicated electronics,” says Alexander Gaeta, Rickey Professor of Applied Physics and Materials Science at Columbia University. “Our very broad dual combs have a moderate spacing between the successive lines of the frequency comb, as compared to gas spectrometers which can get away with a less broad dual comb but need a fine spacing between the lines of the comb. There is now a path for trying to integrate the entire device into a phone or a wearable device.”

REFERENCES

1. N. G. Pavlov et al., Opt. Lett., 42, 514–517 (2017).

2. A. Dutt et al., Sci. Adv., 4, 3, e1701858 (Mar. 2, 2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.