Picarro CRDS detects "alarming" level of methane emissions from fossil fuel sites

Per an article in Environmental Science & Technology, atmospheric methane (CH4) was measured using a mobile laboratory with cavity ring-down spectroscopy (CRDS) equipment from Picarro (Santa Clara, CA) to quantify fugitive methane (CH4) emissions from Oil and Natural Gas (ONG) operations in the Barnett Shale area in Texas.

RELATED ARTICLE: OA-ICOS spectroscopy measures atmospheric methane

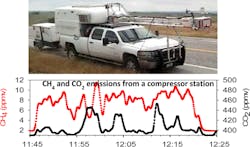

Two Picarro CRDS instruments (G2201-i and G2132-i) were used to measure CO2 and CH4 with 1.0 to 1.5 s time resolution. The CH4 signal from the fast-response Picarro instrument served as a good indicator of ONG plumes. The team drove slowly for plume scanning directly downwind of ONG facilities and in total, drove about 3,700 km while taking CH4 measurements. The number of facilities sampled was 152, comprised of 125 well pads, 13 compressor stations, 2 gas processing plants, and 12 landfills. Emission rates from several ONG facilities and landfills were estimated using an Inverse Gaussian Dispersion Model and the Environmental Protection Agency (EPA) Model AERMOD.

Model results show that well pads emissions rates had a fat-tailed distribution, with the emissions linearly correlated with gas production. Using this correlation, the studies estimated a total well pad emission rate of 1.5 x 105 kg/h in the Barnett Shale area. It was found that methane emissions from compressor stations and gas processing plants were substantially higher, with some "super emitters" having emission rates up to 3447 kg/h, more then 36,000-fold higher than reported by the Environmental Protection Agency (EPA) Greenhouse Gas Reporting Program (GHGRP).

The CRDS study concluded that landfills are also a significant source of CH4 in the Barnett Shale area, and they should be accounted for in the regional budget of CH4.

SOURCE: Environmental Science & Technology; http://pubs.acs.org/doi/full/10.1021/es5063055

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.