Laser Components FBPI fiber features high solarization resistance

FBPI fiber features high solarization resistance and transmission across a range from 200 to 2100 nm. The buffer material for the UV fibers is mostly polyimide, which can withstand temperatures up to 300°C. Other buffer materials such as acrylate or Tefzel are available. FC, ST, SMA, high-power SMA, and other connectors can be assembled with the fibers.

Laser Components

Hudson, NH

www.laser-components.com

-----

Press release for your consideration,

Made in Germany

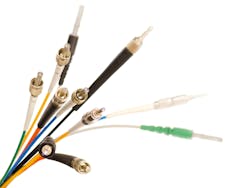

Fiber Assemblies for UV Wavelengths

Transmitting UV wavelengths with optical fibers is challenging. LASER COMPONENTS now presents a perfect solution: assembled patchcords based on UV fibers for immediate application. UV fiber assemblies are required for many applications, for example in fluorescence spectroscopy, UV laser power transmission, medical technology, or UV illumination tasks. Depending on the application and the wavelength different types of fibers are available.

At very short wavelengths, the use of solarization-resistant fibers with low UV damage is recommended. In the wavelength range from 190 nm to 240 nm in particular, damage to conventional optical fibers leads to losses in transmission and even blinding of the fiber (solarization). Many applications require a broadband fiber. Our FBPI fiber is particularly suitable: it features a high solarization resistance and has excellent transmission properties across a wide wavelength range from 200 nm to 2100 nm.

The buffer material for the UV fibers is mostly polyimide, which is able to withstand temperatures of up to 300°C. Other buffer materials such as acrylate or Tefzel are available upon request. FC, ST, SMA, high-power SMA, and other connectors can be assembled with the UV fibers. For the cladding PVC, PTFE and metal can be chosen - of course other claddings are also available.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!